| 2025 №04 (05) |

DOI of Article 10.37434/sem2025.04.06 |

2025 №04 (07) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2025, #4, 37-42 pages

Segregation in a steel ingot and possibilities for its lowering

F.K. Biktagirov, K.B. Zlygoriev

E.O. Paton Electric Welding Institute of the NAS of Ukraine 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: biktagirfk@ukr.netAbstract

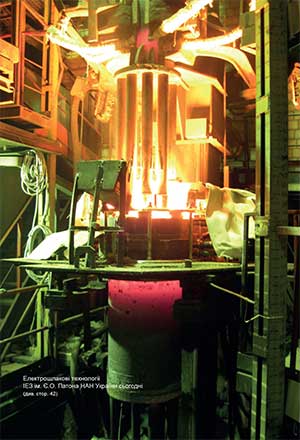

The problem of chemical macroheterogeneity in steel ingots is considered, which is caused by redistribution (segregation) of elements dissolved in iron, between the solid and liquid phases during metal solidification. It is determined that carbon, sulphur and phosphorus are the most prone to segregation. Their accumulation leads to formation of the general and local forms of chemical macroheterogeneity. Two main hypotheses are considered as to the mechanism of formation of the axial (V-shaped) and off-center (A-shaped) defects of chemical heterogeneity and the role of the two-phase zone of their development. Increased content of healing additives in the defective zones creates a risk of premature failure or even breaking up of the product made from the ingot. Results of studying a roll from 70Kh3GNMF steel are given, which confirm that positive segregation is observed in a 48 ton ingot from which the roll was made, with exceeding the admissible carbon content in individual zones. Also noted is the manifestation of V-shaped and A-shaped defects, where sulphur content is 2...5 times higher. Traditional and modern technological means of preventing the macrosegregation are considered: reduction of impurities, multipouring, as well as hot-top pulsed magnetic oscillation (HPMO) and electroslag heating and stirring (ESHS). It is shown that forced convection of the melt inside the ingot promotes reducing the extent of the two-phase zone, homogenizing of the composition and potential lowering of chemical macroheterogeneity. The authors emphasize that application of the methods of external influence, in particular, ESHS method, allows not only eliminating the shrinkage defects, but also enhancing the chemical homogeneity of steel, and it is indicative of the good prospects for its application to improve the quality of the steel ingots. 22 Ref., 2 Tabl., 4 Fig.

Keywords: steel ingot, segregation, chemical macroheterogeneity, defects, external influence, metal heating and stirring

Received: 01.10.2025

Received in revised form: 11.12.2025

Accepted: 22.12.2025

References

1. Ageev, N.V. (1947) The nature of chemical bonds in metallic alloys. Moscow, Leningrad: Publishing House of the Academy of Sciences of the USSR [in Russian].2. Weingart, U. (1967) Introduction to the physics of metal crystallization. Moscow, Mir [in Russian].

3. Flemings M.C. (1974) Solidification processing materials. In: Science and engineering series. New York.

4. Saratovkin, D.D. (1957) Dendritic crystallization. Moscow, Metallurgizdat [in Russian].

5. Gulyaev, B.B. (1950) Solidification and heterogeneity of steel. Moscow, Metallurgizdat [in Russian].

6. Efimov, V.A. (1976) Steel casting and crystallization. Moscow, Metallurgy [in Russian].

7. Tageev, V.M. (1952) Heterogeneity of the structure of steel ingots. In: Steel ingot. Moscow, Metallurgizdat, 40-66 [in Russian].

8. Tageev, V.M., Smironov, Yu.D. (1958) Study of the formation of off-axis heterogeneity in steel ingots and castings. In: Solidification of Metals. Moscow, Mashgiz, 352-372 [in Russian].

9. Smirnov, Yu.D. (1969) On the mechanism of the formation of off-axis heterogeneity in steel ingots. Problems of the Steel Ingot, 3, 49-53 [in Russian].

10. Suzuki, K., Taniguchi, K., Watanabe, J. (1979) Control of macro-segregation in large forging ingots by vacuum carbon deoxidation. In: Proc. of the Sixth Inter. Conf. on Vacuum Metallurgy, San Diego, California.

11. Suzuki K., Taniguchi K. (1981) The mechanism of reducing «A» in steel ingot. Tranact. Iron and Steel Inst., Jap., 4, 235–342. https://doi.org/10.2355/isijinternational1966.21.235

12. Efimov, V.A. (1969) State and prospects of research in the field of improving steel casting and the quality of steel ingots. In: Problems of the steel ingot. Moscow, Metallurgizdat, 3-24 [in Russian].

13. Dickenson, H.S. (1965) Segregation in large steel ingots. Iron and Steel Institute, 1, 177-196.

14. Wutao, T., Xiong, Z., Houfa, S., Baicheng, L. (2014) Numerical simulation on multiple pouring process for a 292t steel ingot. Research and Development, 11(1), 52-58.

15. Barabash, V.V., Biktagirov, F.K. (2024) Application of external influence in the production of steel ingots. Suchasna Elektrometalurhiya, 1, 40-48 [in Ukrainian]. https://doi.org/10.37434/sem2024.01.05

16. Shapovalov, V., Biktagirov, F., Gnatushenko A. et al. (2020) Method for preparing steel ingot. Pat. Chine ZL2018 1 1041752.7, 02.06.2020.

17. Barabash, V.V., Biktagirov, F.K., Shapovalov, V.O. et. al. (2024) New method for improving physical homogeneity of steel ingots. In: Proc. of the VII Inter. Conf. on Welding and Related Technologies, WRT 2024, 7-10 October, Yaremche, Ukraine. https://doi.org/10.1201/9781003518518

18. Barabash, V.V., Biktahirov, F.K., Shapovalov, V.O., Hnatushenko, O.V. (2004) The influence of metal heating and stirring on the conditions of steel ingot solidification. In: Proc. of the 18th Inter. Conf. on scientific on Science and Education, Hajduzsobozlo, Hungary, 04-11 January.

19. Biktagirov, F.K., Barabash, V.V. (2025) Influence of electroslag heating and stirring of metal on the physical homogeneity of experimental 40Kh steel ingots. Casting Processes, 2(160), 10-19 [in Ukrainian]. https://doi.org/10.15407/plit2025.02.010

20. Li, H.C., Liu, Y.X., Zhang, Y.H. et al. (2018.) Effects of hot top pulsed magneto-oscillation on solidification structure of steel ingot. China Foundry, 15, 110-116. https://doi.org/10.1007/s41230-018-7198-z

21. Zhang, F., Zhong, H.G., Yang, Y.Q. et al. (2022) Improving ingot homogeneity by modified hot-top pulsed magneto-oscillation. J. Iron Steel Res. Int., 29, 1939-1950. https://doi.org/10.1007/s42243-022-00785-5

22. Zhong, H., Huang, J., Han, K. et al. (2024) Homogenization technology for heavy ingots: Hot-top pulsed magneto-oscillation. Metallurgical and Materials Transact., 55, 1083-1097. https://doi.org/10.1007/s11663-024-03019-z