(You are viewing the simplified file contents)

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.

| SCIENTIFIC AND TECHNICAL | |

| Pokhodnya I.K. Mathematical modelling of processes of interaction of metal with gases in arc welding. | 2 |

| Results of thermodynamic investigations of interaction of molten metal with a gas, containing hydrogen, oxygen and compounds of fluorine, and also with a slag phase are given. Taking into account the non-stationary conditions and variable rate of crystallization the laws of redistribution of hydrogen in a crystallizing weld pool are established. The formulated mathematical models are based on a differential equation of mass transfer, in particular, the Fick's equation with boundary conditions of Stefan type on the moving phase interface. Kinetics of hydrogen redistribution near the fusion line, and also in molten metal at a cellular crystallization was studied. The process of growth of a gas bubble in weld pool is described. | |

| Lebedev V.K. and Pismenny A.A. Power system of flash-butt welding machines with a transistor inverter. | 10 |

| The paper gives analysis and comparison of various power systems of flash-butt welding machines by their power characteristics, namely single-phase systems of industrial frequency and three-phase systems with converters of frequency and phase number (with thyristor inverters and bipolar transistors). It is shown that a system with an inverter converter, using power transistors, has an advantage over the system with a thyristor converter in terms of distribution of currents in the mains phases, as power consumer. High power factor, close weight and dimensional indices of the lower-frequency transformer to those of commercial-frequency transformer and absence of powerful rectifier diodes in the secondary circuit are indicative of the good prospects for application of the transistor inverter with the set frequency of 30 Hz. | |

| Makhnenko V.I., Korolyova T.V. and Lavrinets I.G. Computer system for selection of welding consumables for arc welding of structural steels. | 12 |

| Structure of the computer system developed by the authors for rational selection of consumables for electric arc welding of structural steels is described. The system is based on mathematical modelling of physical-metallurgical phenomena occurring during arc welding using data provided by manufacturers of welding consumables on chemical composition of deposited metal, welding parameters and conditions, as well as deposition efficiency. | |

| Skulsky V.Yu., Tsaryuk A.K., Vasiliev V.G. and Strizhius G.N. Structural transformations and weldability of hardening high-strength steel 20KhN4FA. | 17 |

| Transformation of austenite in steel 20KhN4FЂ (GOST 4543-71) under continuous cooling conditions has been studied. Hardening of steel to form fully martensitic structure takes place at cooling rates of more than 20 oC/s, while partially bainitic decomposition occurs at lower cooling rates. Preheating to a temperature of 250-300 oC leads to a dramatic increase in cold crack resistance, which seems to be associated with sufficient conditions ensured for the gamma-bainite transformation to take place. The latter is accompanied by partial self-tempering and increase in ductility of the HAZ metal of a welded joint. Issues related to selection of the preheating temperature are also considered. | |

| Efimenko N.G. and Nesterenko S.V. Intercrystalline corrosion resistance of austenitic deposited metal microalloyed with REM. | 22 |

| Investigations were performed of the influence of microalloying chromium-nickel deposited metal of 18-10 type with yttrium and cerium oxide on its intercrystalline corrosion resistance. A positive role of modifying by cleaning the crystal boundaries and more favorable distribution of intermetallic inclusions is demonstrated. | |

| Balitsky A.I., Kostyuk I.F. and Krokhmalny O.A. Physical-mechanical non-homogeneity of welded joints of high-nitrogen Cr-Mn steels and their corrosion resistance. | 26 |

| Formation of physical-mechanical heterogeneity in metal of welded joints depending on weld metal alloying is considered. The welds alloying with nitrogen provides the higher electrochemical homogeneity of the joints. | |

| INDUSTRIAL | |

| Titov V.A., Danilchenko B.V., Volkov A.N., Bryzgalin A.G., Polishchuk S.M., Koritsky V.A. and Andreev V.V. Pilot Plant of Welding Equipment of the E.O. Paton Electric Welding Institute of the NAS of Ukraine in the new conditions of economy. | 30 |

| Peculiarities of the PWI Pilot Plant evolution in the conditions of transition to the market economy in Ukraine are considered. System and nomenclature ranges of the welding equipment manufactured currently are presented. | |

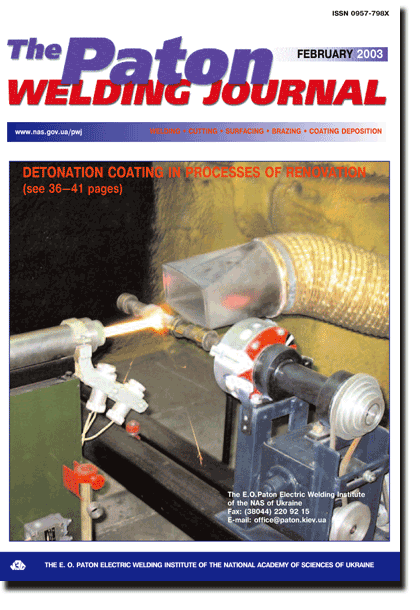

| Astakhov E.A. Detonation system "Perun-S" for deposition of protective coatings. | 36 |

| Basic units were developed and a prototype of the automatic detonation system was made for deposition of coatings with widened operational capabilities, allowing it to be successfully applied for handling both research and production problems. | |

| Kononenko V.Ya. State-of-the-art of underwater welding and cutting in Ukraine. | 41 |

| The paper analyzes the state-of-the-art of underwater welding and cutting in Ukraine. It is established that coated-electrode wet welding now is the main process of underwater welding. In Ukraine practically all the metal structures are cut underwater by applying tubular-electrode oxy-electric cutting. Other underwater cutting processes have not been used lately. | |

| Kriventsov A.N., Lysak V.I., Kuzmin V.I. and Yakovlev M.Ya. Restoration by explosion welding of connecting surfaces of coupler locks. | 46 |

| Technology for repair of worn out connecting surfaces of coupler locks by explosion welding is described. Parameters of the process of explosion welding of cladding plates to the locks and results of mechanical and full-scale tests of repaired locks are given. | |

| BRIEF INFORMATION | |

| Kiselevsky F.N., Butakov G.A., Dolinenko V.V. and Shapovalov E.V. Optical sensor for butt following at gap sizes close to zero. | 48 |

| Approach is suggested to the construction of optical sensor system for determination of the trajectory of a butt made without edge grooving with a gap close to zero. The sensor allows eliminating several disadvantages of the luminous section method and can serve as a beneficial addition to it. | |

| Gnatenko M.F. Device PKR-3 for control of variations in thickness of welding electrode coverings. | 50 |

| Methods for evaluation of variations in thickness of electrode coverings are considered. Specifications of a new device of the PKR-3 model are given. | |

| Method and equipment for pulsed-arc MIG welding with automatic stabilisation of the process. | 52 |

| NEWS | |

| International Seminar "Modern Technologies and New Structural Materials in Chemical Engineering and Industry". | 53 |

(You are viewing the simplified file contents)

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 16 $ |

| AS/EUR | 180 € | 30 € | 25 € | 15 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 16 $ |

| TPWJ/EUR | 360 € | 30 € | 25 € | 15 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 16 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 15 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 16 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.