(You are viewing the simplified file contents)

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.

| SCIENTIFIC AND TECHNICAL | |

| Kuchuk-Yatsenko S.I., Shvets Yu.V., Dumchev E.A., Shvets V.I., Mikitin Ya.I., Taranenko S.D. and Nikitina N.N. Flash-butt welding of railway frogs with rail ends using an intermediate insert | 2 |

| Information is given about the technology of a pulsed flash-butt welding of railway frogs using inserts of austenitic steels. Technology provides extension of the frog life even without application of postweld heat treatment of joints. | |

| Yushchenko K.A. and Derlomenko V.V. Analysis of modern views on weldability | 5 |

| Analysed are some international and national standards, as well as publications on definition and evaluation of weldability. The analysis conducted is summarised and key points are highlighted by an example of standards ISO 581Д1980 and DSTU 3761.1Д98. It is shown that the existing views on weldability (joinability) of materials do not correspond to modern approaches to making permanent joints and require revision. | |

| Ishchenko A.Ya., Mashin V.S. and Pashulya M.P. Technological features of twin-arc consumable electrode pulsed welding of aluminium alloys | 10 |

| Some peculiar features of a pulsed twin-arc consumable electrode welding of aluminium alloy AMg6 using two pulsed power sources with synergic control of process conditions and parameters of the welding torch ensuring feeding of isolated electrode wires are shown. | |

| Savitsky A.M., Vasiliev V.G., Savitsky M.M. and Vashchenko V.N. Influence of the heating stage on structure formation of welded joints on hardening steels | 15 |

| Studies have proved that formation of structure of a welded joint on high-strength steels starts at the stage of its heating at temperatures above Ac3, while at the cooling stage this process ends in overcooled austenite transformation. The main factor determining the role of the heating stage in formation of metal structure is the rate of heating of the welded joint, which is responsible for temperature Ac3. | |

| Markashova L.I., Grigorenko G.M., Valevich M.l. and Petrov S.V. Features of the structure of surface metal layers in railway wheel treads after plasma treatment | 18 |

| It is shown that adjustment of the temperature-rate modes of wheel heating and cooling in the range of working parameters of plasma equipment enables variation of the structural-phase condition of the surface, thus allowing microstructure optimization and providing high values of mechanical properties. | |

| Palamarchuk B.I., Pashchin N.A. and Manchenko A.N. Improvement of fatigue fracture resistance of sheet structures by the method of local pulse action | 22 |

| The paper gives the results of studying pulsed explosion treatment of flat samples of D16 alloy to prevent initiation and propagation of fatigue cracks. Treatment is based on a practically instantaneous generation of configuration fields of residual compression stresses, that prevents heating of the treated metal. Special schematics of pulsed treatment were developed to generate fields of a specific configuration. | |

| INDUSTRIAL | |

| Bernadsky V.N. and Makovetskaya O.K. Current status of welding fabrication in China | 26 |

| The paper presents the data on the status of welding consumable and welding equipment manufacturing, and welding technology market in China, which allows evaluation of the overall current level of welding fabrication and trade in China, and also gives their development prediction. | |

| Nazarenko O.K. and Lokshin V.E. Dynamic characteristics of high-voltage power sources for electron beam welding | 31 |

| Transient processes occurring in high-voltage circuits of modern power sources of welding guns are considered. It is shown experimentally that with a pulsed change in the beam current the accelerating voltage oscillations in a power source based on the high-frequency transistorized converter exceed to a great degree the limits of requirements of standard ISO 14744-1:2000. The conclusion is made about prospects of equipping these power sources with control electron tubes when a key mode of operation is used. | |

| Denikin E.I., Netesa Yu.D. and Netesa A.D. Carbon dioxide gas heaters for mechanised arc welding | 34 |

| Specifications of carbon dioxide heaters for several types of gas feeding system intended for semi-automatic gas metal arc devices are analysed. The heaters characterised by heat transfer in a viscous sub-layer meet to the fullest degree the main technology and consumer requirements. | |

| Zhadkevich A.M. Electric heat sources for brazing | 40 |

| History of application of electric heat sources for brazing of different materials is described. Specifics and capabilities of the processes, performed using equipment based on electric heating, are analyzed. Contribution of individual specialists to the development of equipment and technologies of brazing is outlined. | |

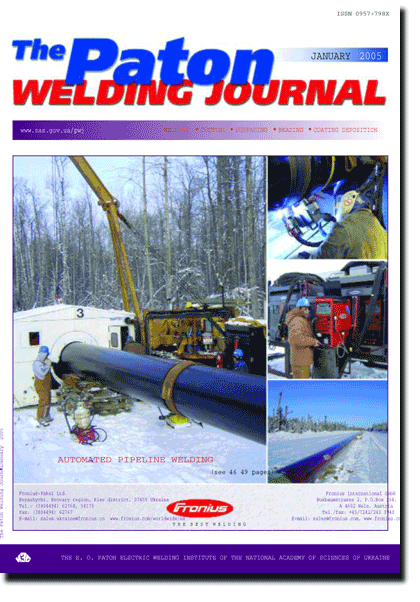

| Automated pipeline welding | 46 |

| BRIEF INFORMATION | |

| Kasatkin O.G. Estimation of impact strength of low-alloy weld metal | 50 |

| Dependence of impact strength of low-alloy weld metal on its composition and mechanical properties in tensile tests is considered. It is shown that, along with the content of main alloying elements, specific fracture energy and yield strength are the informative factors for estimation of impact strength of the weld metal. | |

(You are viewing the simplified file contents)

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 16 $ |

| AS/EUR | 180 € | 30 € | 25 € | 15 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 16 $ |

| TPWJ/EUR | 360 € | 30 € | 25 € | 15 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 16 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 15 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 16 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.