| 2021 №04 (04) |

DOI of Article 10.37434/sem2021.04.05 |

2021 №04 (06) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2021, #4, 32-37 pages

Remelting wastes of titanium and titanium alloys under the conditions of plasma-arc melting

V.R. Burnashev, Yu.O. Nykytenko, V.V. Barabash, V.O. Shapovalov

E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., Kyiv, 03150, Ukraine. E-mail: office@paton.kiev.ua

Abstract

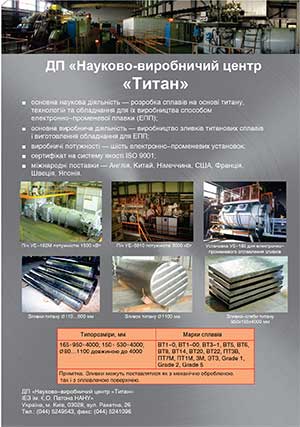

Possibilities are considered of processing titanium and titanium wastes under the conditions of plasma-arc remelting into a through crucible in the form of sublimates, which formed in electron beam furnaces and gate systems from VT5 type alloy, produced in vacuum induction furnaces. Possibilities of plasma-arc skull melting at processing these wastes into small ingots and 70 % ferrotitanium were studied. Hydrogen behaviour in furnace atmosphere at remelting of the above-mentioned wastes was investigated. It is shown that under the conditions of plasma-arc remelting it is possible to process titanium and titanium alloy wastes into billets for further remelting, castings and ferrotitanium. Ref. 9, Tabl. 3, Fig. 7.

Keywords: plasma-arc remelting; plasma-arc skull remelting; titanium; ferrotitanium; titanium alloys; remelting of titanium wastes; ingots

Received 05.11.2011

References

1. Garmata, V.L., Petrunko, A.N., Galitsky, N.V. et al. (1983) Titanium. Moscow, Metallurgiya [in Russian].2. Konstantinov, V.S., Shapovalov, V.A., Davydov, S.I. et al. (2009) Production of consumable electrodes from titanium sponge for remelting in skull casting furnaces. Advances in Electrometallurgy, 2, 123‒126

3. Paton, B.E., Trigub, N.P., Akhonin, S.V. (2005) Producing of titanium ingots from whole blocks of sponge titanium by electron beam melting method. Titan., 2, 23–36.

4. Trigub, N.P., Akhonin, S.V., Zhuk, G.V. et al. (2006) Electron beam melting of uncrushed sponge titanium blocks. Ibid., 4, 5‒7.

5. Paton, B.E., Medovar, B.I., Saenko, V.Ya., Kumysh, V.N. (1995) Production of ingots of titanium and its alloys by remelting of titanium sponge and scrap. Problemy Spets. Elektrometallurgii, 3, 14–23 [in Russian].

6. Latash, Yu.V., Konstantinov, V.S., Gorbenko, V.A. et al. (1989) Industrial application of low-temperature plasma in smelting of ingots of electrodes from low-grade spongy titanium for production of titanium stop valves. Ibid., 3, 71–75 [in Russian].

7. Shejko, I.V., Shapovalov, V.A., Konstantinov, V.S. (2007) Alternative technologies of remelting of industrial wastes of titanium and alloys thereof. Advances in Electrometallurgy, 3, 44–50.

8. Dolzhikov, V.V., Latash, Yu.V., Shekhter, S.Ya. et al. (1983) Some investigations of melting of secondary titanium ingots in U-599 unit. Problemy Spets. Elektrometallurgii, 18, 85–88 [in Russian].

9. Zhadkevich, M.L., Shapovalov, V.A., Teslevich, S.M. et al. (2004) Study of gas phase composition in plasma-arc melting of titanium from a pressed billet. Advances in Electrometallurgy, 4, 21‒24.