| 2023 №03 (01) |

DOI of Article 10.37434/tdnk2023.03.02 |

2023 №03 (03) |

"Tekhnichna Diahnostyka ta Neruinivnyi Kontrol" (Technical Diagnostics and Non-Destructive Testing) #3, 2023, pp. 10-15

Numerical-instrumental method of thermographic control of the state of large-sized structures and constructions

O.S. Milenin, V.Yu. Glukhovskyi, O.A. Velykoivanenko, V.A. Lytvynenko

E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: office@paton.kiev.uaA numerical-instrumental approach of thermographic control was developed to improve the efficiency of contactless control of the state of difficult-of-access parts of large-sized structures and constructions. It consists in integrated application of industrial thermal imaging instruments and computational methods of analysis of temperature fields in the studied structures. This allows improving the accuracy of determination of the geometrical features of the defects and reducing the labour consumption of operations of technical diagnostics of the state. Application of the developed approach was demonstrated on typical examples of contactless control of the technical state of industrial chimneys. 10 Ref., 2 Tabl., 6 Fig.

Keywords: thermographic control, technical state, flaw detection, industrial chimneys, heat transfer

Received: 03.04.2023

References

1. Fox, M., Coley, D., Goodhew, S., P. de Wilde (2014) Thermography methodologies for detecting energy related building defects. Renewable and Sustainable Energy Reviews, 40, 296-310. https://doi.org/10.1016/j.rser.2014.07.1882. DSTU B EN 13187:2011 Thermal performance of buildings - Qualitative detection of thermal irregularities in building envelopes - Infrared method.

3. Kylili, A., Fokaides, P.A., Christou, P., Kalogirou, S.A. (2014) Infrared thermography (IRT) applications for building diagnostics: A review. Applied Energy, 134, 531-549. https://doi.org/10.1016/j.apenergy.2014.08.005

4. Miguel, M., Chong, A., Biljecki, F., Miller, C. (2022) Infrared thermography in the built environment: A multi-scale review. Renewable and Sustainable Energy Reviews, 165, 112540. https://doi.org/10.1016/j.rser.2022.112540

5. Wu, Z., Qin, S., Zhang, P., Pan, Z. (2023) Damage evolution in braided composite tubes under axial compression studied by combining infrared thermography and X-ray computed tomography. Composite Structures, 307, 116634. https://doi.org/10.1016/j.compstruct.2022.116634

6. Xie, H., Fang, H., Li, X. et al. (2021) Low-velocity impact damage detection and characterization in composite sandwich panels using infrared thermography. Composite Structures, Vol. 269, 114008. compstruct.2021.114008 https://doi.org/10.1016/j.compstruct.2021.114008

7. Karkhin, V.A. (2019) Thermal Processes in Welding. Singapore, Springer Singapore. https://doi.org/10.1007/978-981-13-5965-1

8. Akhonin, S.V., Milenin, A.S., Pikulin, A.N. (2005) Modeling of processes of evaporation of alloying elements in EBSM of cylindrical ingots produced from Ti-base alloys. Advances in Electrometallurgy, 1, 21-25.

9. (1991) Physical quantities. Handbook. Eds by I.S. Grigoriev, E.Z. Mejlikhov. Moscow, Energoatomizdat [in Russian].

10. https://eco-obogrev.com/ua/a233242-spravka-plotnostteploprovodnost.html

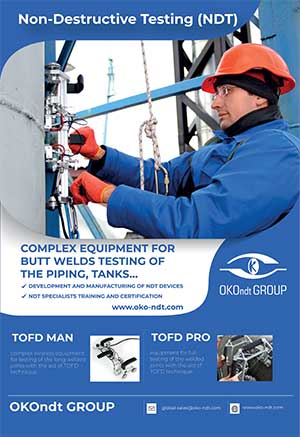

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.