| 2020 №03 (06) |

DOI of Article 10.37434/sem2020.03.07 |

2020 №03 (08) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2020, #3, 49-53 pages

Effect of miсrostructural features on corrosion resistance of titanium alloys produced by powder technologies

I.M. Pogrelyuk1, D.G. Savvakin2, O.O. Stasyuk2, Kh.S. Shlyakhetkak1

1G.V. Karpenko Physico-Mechanical Institute of the NAS of Ukraine. 5 Naukova Str., 79060, Lviv, Ukraine. E-mail: pminasu@ipm.lviv.ua

2G.V. Kurdyumov Institute of Metal Physics. 36 Vernadskii Prosp. 03680, Kyiv, Ukraine. E-mail: metall@imp.kiev.ua

Abstract

Corrosion resistance of sintered titanium alloy Ti–6Al–4V in different structural states was investigated by gravimetric and electrochemical methods in 20 % aqueous solution of hydrochloric acid. By changing the technological parameters in the process of manufacturing the sintered alloy, it was possible to control its porosity in the range of 1…4 %. A general tendency of slowing down of the corrosion processes with decrease in porosity was established. It is shown that reducing the volume fraction of pores to 1…2 %, as well as spheroidizing them and reducing their size increase the corrosion resistance. Ref. 9, Tabl. 2, Fig. 6.

Keywords: titanium alloy Ti–6Al–4V; powder metallurgy; powder; titanium hydride; hydrochloric acid; corrosion resistance

Received 13.07.2020

References

1. Lutjering, G., Williams, J.C. (2007) Titanium. Berlin Heidelberg, Springer, 2nd Ed.2. Niinomi, M., Nakai, M., Hieda, J. (2012) Development of new metallic alloys for biomedical applications. Acta Biomaterialia, 8, 3888-3903. https://doi.org/10.1016/j.actbio.2012.06.037

3. Fang, Z.Z., Paramore, J.D., Sun, P. et al. (2018) Powder metallurgy of titanium - past, present and future. Intern. Mater. Rev., 63(7), 407-459. https://doi.org/10.1080/09506608.2017.1366003

4. Ma Qian, Froes, F.H. (2015) Titanium powder metallurgy: Science, technology and applications. Elsevier.

5. Froes, F.H., Eylon, D. (1990) Powder metallurgy of titanium alloys. Intern. Mater. Rev., 35(3), 162-182. https://doi.org/10.1179/095066090790323984

6. Ivasishin, O.M., Savvakin, D.G., Gumenyak, N.M. (2011) Dehydrogenation of powder titanium hydride and its role in sintering activation. Metallofizika i Novejshie Tekhnologii, 33(7), 899-917 [in Russian].

7. Ivasishin, O.M., Savvakin, D.G., Gumenyak, M.M., Bondarchuk, A.B. (2012) Role of surface contamination in titanium PM. Key Engineering Materials, 520, 121-132. https://doi.org/10.4028/www.scientific.net/KEM.520.121

8. Ivasishin, O.M., Savvakin, D.G. (2010) The impact of diffusion on synthesis of high-strength titanium alloys from elemental powder blends. Ibid., 436, 113-121. https://doi.org/10.4028/www.scientific.net/KEM.436.113

9. Balshin, M.Yu. (1972) Scientific fundamentals of powder metallurgy and fiber metallurgy. Moscow, Metallurgiya [in Russian].

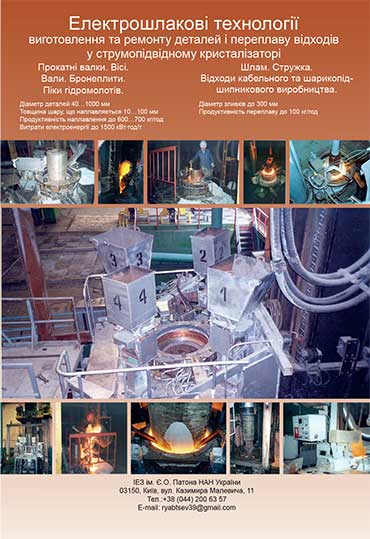

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.