| 2021 №03 (02) |

DOI of Article 10.37434/sem2021.03.03 |

2021 №03 (04) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2021, #3, 13-18 pages

Production of titanium ingots with regulated oxygen content by electron beam melting

S.V. Akhonin1, O.M. Pikulin1, V.O. Berezos1, A.Yu. Severin1, O.G. Erokhin2

1E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: office@paton.kiev.ua

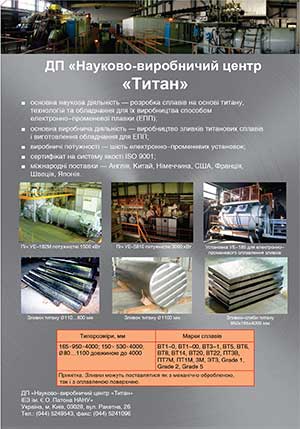

2SC «SPC «Titan» of the E.O. Paton Electric Welding Institute of the NAS of Ukraine». 26 Raketna Str., 03028, Kyiv, Ukraine. Е-mail: titan.paton@gmail.comни». 03028, м. Київ, вул. ракетна, 26. Е-mail: titan.paton@gmail.com

Abstract

Comprehensive research work was performed to produce ingots of Grade 2 titanium alloy of 600 mm diameter and ingots of Grade 3 titanium alloy of 1100 mm diameter and up to 3 m length with regulated oxygen content of 0.12…0.16 % by the method of cold-hearth electron beam melting in the production facilities of SC «SPC «Titan» of the E.O. Paton Electric Welding Institute of the NAS of Ukraine» in multifunctional electron beam unit UE5810. A method of forming the charge billet and a formula for calculation of the amount of TiO2 powder for alloying are proposed. Defectfree ingots of titanium alloys of Grade 2 and Grade 3 with a regulated oxygen content were produced and the range of deviation of its distribution in the ingot metal of ± 0.02 % was ensured. It is shown that the proposed modes of electron beam heating of the consumable billet, metal melting in the cold-hearth and in the mould, as well as the melting rate ensure complete dissolution of titanium dioxide particles in the cold hearth, and absence of defects in the produced ingots, enriched in oxygen. Ref. 14, Tabl. 1, Fig. 5.

Keywords: cold-hearth electron beam melting; electron beam unit; titanium ingot; oxygen; regulated oxygen content; titanium dioxide; melting rate; macrostructure

Received 22.06.2021

References

1. Olejnik, T.A., Guryanova, T.P., Kolobov, G.A. et al. (2010) Development of technologies for the extraction, enrichment and processing of titanium raw materials in the world and in Ukraine. Metalurgiya: Zb. Nauk. Prats of ZGIA, 22, 44–59 [in Russian].2. Chervony, I.F., Telin, V.V., Pozhuev, V.I. et al. (2007) Titanium and fields of its application. In: Proc. of Int. Sci.-Tech. Conf. on Ti-2007 in CIS (15–18 Apr. 2007, Yalta). Kiev, 2007, 314–325 [in Russian].

3. (2013) Titanium Metal: Market Outlook to 2018. Sixth Ed. Roskill Information Services Ltd, USA.

4. Osipenko, A.V. (2015) Development of technology of producing raw materials for titanium alloys from substandard titanium sponge. Eastern-European J. of Enterprise Technologies, 4(5), 28-32 [in Russian]. https://doi.org/10.15587/1729-4061.2015.47789

5. Cheng-Lin, Li, Yang, Yu, Wen-Jun, Ye et al. (2015) Effect of boron addition on microstructure and property of low cost beta titanium alloy. In: TMS 2015, 144th Annual Meeting & Exhibition, 1167-1172. https://doi.org/10.1007/978-3-319-48127-2_141

6. Davydov, S.I., Shvartsman, L.Ya., Ovchinnikov, A.V., Teslevich, S.M. (2006) Some peculiarities of titanium alloying with oxygen. In: Proc. of Int. Sci.-Tech. Conf. on Ti-2006 in CIS (21–24 May, 2006, Suzdal, Russia). Kiev, Naukova Dumka, 253–257 [in Russian].

7. Ryabtsev, A.D., Troyansky, A.A. (2011) Refining and alloying of titanium in the process of electroslag remelting in a chamber furnace. Advances in Electrometallurgy, 9(1), 56–57.

8. Kollerov, M.Yu., Spektor, V.S., Skvortsova, S.V. (2015) Problems and prospectives of application of titanium alloys in medicine. Titan, 48(2), 42–53 [in Russian].

9. Ratiev, S.N., Ryabtseva, O.A., Troyansky, A.A. et al. (2010) alloying titanium with oxygen from the gas phase in chamber electroslag remelting of titanium sponge. Advances in Electrometallurgy, 8(2), 87–92.

10. Egorova, Yu.B., Davydenko, L.V., Mamonov, I.M. (2015) Influence of oxygen alloying on mechanical properties of rods from titanium and Ti–6Al–4V alloy. Int. Research J., 41(10), Pt 2, 49–51 [in Russian]. DOI: https://doi.org/10.18454/ IRJ.2015.41.154

11. Kostenko, V.I., Kruglenko, M.P., Kalinyuk, A.N., Pap, P.A. (2012) Production by of defect-free titanium ingots with controlled oxygen content by electron beam remelting. Advances in Electrometallurgy, 10(1), 29–32.

12. Kablov, E.N. (2012) Strategic trends of development of materials and technologies of their processing for the period up to 2030. Aviats. Materialy i Tekhnologii, S, 7–17 [in Russian].

13. Iliin, A.A., Kolachev, B.A., Polkin, I.S. (2009) Titanium alloys. Composition, structure, properties. Moscow, VILS-MATI [in Russian].

14. Akhonin, S.V., Kruglenko, M.P., Kostenko, V.I. (2011) Mathematical modeling of the process of dissolution of oxygen-containing refractory inclusions in a titanium melt. Advances in Electrometallurgy, 9(1), 13–18.

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.