| 2025 №04 (02) |

DOI of Article 10.37434/sem2025.04.03 |

2025 №04 (04) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2025, #4, 17-25 pages

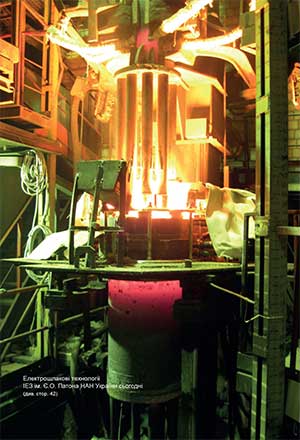

Recycling of nickel alloys by electroslag remelting

Yu.V. Kostetskyi, V.P. Petrenko, E.O. Pedchenko, G.O. Polishko, V.A. Zaitsev

E.O. Paton Electric Welding Institute of the NAS of Ukraine 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: y.kostetsky@paton.kiev.uaAbstract

The paper presents the results of experiments on recycling of nickel alloys through electroslag remelting (ESR) using a current supplying mould. The research was conducted in the P-951 furnace, where rational modes of remelting electrodes of a variable cross-section from nickel alloy waste were determined. The study confirmed the effectiveness of recycling technological waste of EP648 nickel alloy by electroslag remelting using a current-supplying mould. Optimal modes of remelting variable cross-section consumable electrodes were established to ensure process stability through rational power distribution between the electrode and the current-supplying mould. The chemical composition of the produced ingots met the regulatory requirements for the EP648 alloy, and the products made from these ingots successfully passed quality control. The developed single-stage recycling technology allows nickel alloy waste to be returned directly to the production cycle, demonstrating high practical potential for industrial application. The research results can be used to improve the existing metal waste recycling methods and to develop new approaches to processing nickel alloys waste. 23 Ref., 6 Tabl., 7 Fig.

Keywords: recycling, nickel alloy, electroslag remelting, dual-circuit ESR technology, current-supplying mould, ingot

Received: 15.09.2025

Received in revised form: 14.10.2025

Accepted: 12.11.2025

References

1. Branca, T., Colla, V., Algermissen, D. et al. (2020) Reuse and recycling of by-products in the steel sector: Recent achievements paving the way to circular economy and industrial symbiosis in Europe. Metals, 10(345). https://doi.org/10.3390/met100303452. Domenech, T., Bahn-Walkowiak, B. (2019) Transition towards a resource efficient circular economy in Europe: Policy lessons from the EU and the member states. Ecological Economics, 155, 7-19. Elsevier, Amsterdam. https://doi.org/10.1016/j.ecolecon.2017.11.001

3. Xie, J., Xia, Z., Tian, X., Liu, Y. (2023) Nexus and synergy between the low-carbon economy and circular economy: A systematic and critical review. Environmental Impact Assessment Review, 100, 107077. https://doi.org/10.1016/j.eiar.2023.107077

4. Feng, H., Chen, L., Liu, X., Xie, Z. (2017) Construction design for an iron and steel production process based on the objectives of steel yield and useful energy. Inter. J. of Heat and Mass Transfer, 111, 1192-1205. https://doi.org/10.1016/j.ijheatmasstransfer.2017.04.096

5. Watari, T., Mclellan, B. (2024) Decarbonizing the global steel industry in a resource-constrained future - A systems perspective. Philosophical Transact. of the Royal Society A, 382(2284), 20230233. https://doi.org/10.1098/rsta.2023.0233

6. Diener, D.L., Tillman, A.M. (2016) Scrapping steel components for recycling - Isn't that good enough? Seeking improvements in automotive component end-of-life. Resources, Conservation and Recycling., 110, 48-60. https://doi.org/10.1016/j.resconrec.2016.03.001

7. Wu, L., Liu, K., Mei, H. et al. (2022) Thermodynamics analysis and pilot study of reusing medium and high alloy steel scrap using induction melting and electroslag remelting process. Metals, 12(6), 944. https://doi.org/10.3390/met12060944

8. Varvara, D.A.I., Tintelecan, M., Aciu, C. et al. (2019) An assessment of the substance losses from charge composition used to the steelmaking - Key factor for sustainable steel manufacturing. Procedia Manufacturing, 32, 15-21. https://doi.org/10.1016/j.promfg.2019.02.177

9. Gandhewar, V.R., Bansod, S.V., Borade, A.B. (2011) Induction furnace - A review. Inter. J. of Eng. and Techn., 3(4), 277-284.

10. Arh, B., Podgornik, B., Burja, J. (2016) Electroslag remelting: a process overview. Materials and Technology, 50(6), 971-978. https://doi.org/10.17222/mit.2016.108

11. Mitchell, A. (2008) Electroslag technology for aerospace alloys. Advances in Electrometallurgy, 4, 31-36 [in Russian].

12. Walek, J.,Odehnalová, A., Kocich, R. (2024) Analysis of thermophysical properties of electroslag remelting and evaluation of metallographic cleanliness of steel. Materials, 17(18), 4613 https://doi.org/10.3390/ma17184613

13. Biktagirov, F.K., Veretilnyk, O.V., Shapovalov, V.O. et al. (2021) Comparative indices of different methods of processing shavings of high-alloyed steels and alloys. Suchasna Elektrometalurhiya, 4, 11-15 [in Ukrainian]. https://doi.org/10.37434/sem2021.04.01

14. Kuskov, Yu.M., Ryabtsev, I.A., Kuzmenko, O.G., Lentyugov, I.P. (2020) Electroslag technologies of surfacing and recycling of metal and metal-containing waste. Kyiv, Interservice.

15. Mitchell, A. (2021) Electrode manufacture for the remelting processes. Ironmaking & Steelmaking, 48(5), 505-513, https://doi.org/10.1080/03019233.2020.1855690

16. Tsykulenko, A.K., Lantsmann, I.A., Medovar, L.B. et al. (2000) Two-circuit method of electroslag remelting consumable electrodes. Advances in Special Electrometallurgy, 3, 141-144.

17. Dong, Y., Jiang, Z., Cao, H. et al. (2016) Study of single-power, two-circuit ESR process with current-carrying mold. Development of the technique and its physical simulation. Metallurgical and Materials Transact. B, 47(6), 3575-3581. https://doi.org/10.1007/s11663-016-0813-8

18. Medovar, L., Stovpchenko, G., Jianjun, G. (2024) State of the art of electroslag refining and challenges in the control of ingot cleanness. In: Proc. of 12th Inter. Conf. on Molten Slags, Fluxes and Salts MOLTEN 2024. Brisbane, AusIMM, ID: P-04120-D5P7M3.

19. Medovar, L., Fedorovsky, B., Petrenko, V. (2005) ESR with two power sources and process control. In: Proc. of Inter. Symp. on Liquid Metal Processing and Casting, Santa-Fe, New Mexico, 131-135.

20. Pedchenko, Ye., Medovar, L., Kostetsky, Yu. (2022) Electroslag remelting as a method of recycling non-compact highspeed steel tools. In: Proc. of 31st Inter. Conf. on Metallurgy and Materials. Brno, TANGER Ltd, 142-148. https://doi.org/10.37904/metal.2022.4455

21. Pedchenko, Ye.O., Petrenko, V.L., Kostetskyi, Yu.V. et al. (2025) Electroslag remelting of variable cross-section electrodes using a two-circuit scheme. In: Proc. of the VII Inter. Conf. on Welding and Related Technologies WRT 2024. Yaremche, CRC Press, 25-28. https://doi.org/10.1201/9781003518518-5

22. Kuskov, Yu.M., Solovyov, V.G. (2018) Experimental study of slag and metal bath rotation during electroslag process in current-feeding mould. Avtomaticheskaya Svarka, 7, 41-43 [in Russian]. https://doi.org/10.15407/as2018.07.07

23. Reitz J., Wietbrock B., Richter S. et al. (2011) Enhanced homogenization strategy by electroslag remelting of high-manganese TRIP and TWIP steels. Advanced Eng. Materials,13(5), 395-399. https://doi.org/10.1002/adem.201000322

Advertising in this issue:

To order the electronic version of the paper:

Yu.V. Kostetskyi, V.P. Petrenko, E.O. Pedchenko, G.O. Polishko, V.A. ZaitsevRecycling of nickel alloys by electroslag remelting

Electrometallurgy Today №04 2025 p.17-25

The cost of article (pdf): 13 $, 12 €, 150 UAH (1 copy. )

fill in the form below:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.