| 2020 №01 (01) |

DOI of Article 10.37434/sem2020.01.02 |

2020 №01 (03) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2020, #1, 14-25 pages

Heat treatment of high-strength pseudo-β-titanium alloy produced by ebm process and of its welded joints

S.V. Akhonin, V.Yu. Bilous, R.V. Selin, I.K. Petrichenko

E.O. Paton Electric Welding Institute of the NAS of Ukraine 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: office@paton.kiev.ua

Abstract

The effect of several kinds of heat treatment, such as annealing, water quenching, controlled annealing, slow cooling, on the structure and properties of base metal and welded joints of high-strength pseudo-β-titanium alloy, produced by electron beam welding and tungsten electrode argon-arc welding with through penetration was studied. Ingots of a round cross-section of 110 mm diameter from pseudo- β-titanium alloy of Ti–Al–Мо–V–Cr–Zr system were produced by the technology of cold hearth electron beam melting and portioned feed of liquid metal into a water-cooled mould. It is found that the most finely-dispersed structure in the base metal, weld metal and HAZ forms in the metal and joints subjected to water quenching with further ageing. Such heat treatment and structure provide the highest values of ultimate strength of the base metal on the level of 1300…1310 MPa, and of welded joints on the level of 1270…1285 MPa. Here, high values of impact toughness are preserved (23 J/cm2). Ref. 15, Tabl. 3, Fig. 12.

Keywords: pseudo-β-titanium alloys; welding; fusion; heat treatment; microstructure; mechanical features

Received 05.12.2019

References

1. Boyer, R.R., Briggs, R.D. (2005) The use of β-titanium alloys in the aerospace industry. J. of Materials Eng. and Performance, 14(6), 681-685. https://doi.org/10.1361/105994905X75448

2. Cotton, J.D., Briggs, R.D., Boyer, R.R. et al. (2015) State of the art in beta titanium alloys for airframe applications. JOM, 67(6), 1281-1303. https://doi.org/10.1007/s11837-015-1442-4

3. Liu, H., Wang, H., Zhang, Z. et al. (2019) Enhancing the mechanical properties of electron beam welded TC17 titanium alloy joint by post-weld heat treatment. J. of Alloys and Compounds, 810, 151937. https://doi.org/10.1016/j.jallcom.2019.151937

4. Khorev, A.I. (2012) Titanium superalloy VT 19. Tekhnologiya Mashinostroeniya, 6, 2-5 [in Russian].

5. Khorev, A.I. (2010) Theory of alloying and heat treatment of structural (α+β)-titanium alloys of high and super high strength. Vestnik Mashinostroeniya, 7, 32-39 [in Russian].

6. Fan, J.K., Kou, H.C., Lai, M.J. et al. (2013) Hot deformation mechanism and microstructure evolution of a new near β-titanium alloy. Materials Sci. and Eng. A, 584, 121-132. https://doi.org/10.1016/j.msea.2013.07.019

7. Khorev, A.I. (2011) Thermal and thermomechanical treatment of titanium alloys. Russian Eng. Research, 31(12), 1227-1232. https://doi.org/10.3103/S1068798X1112015X

8. Li, M., Xiong, A., Huang, W. et al. (2002) Microstructural evolution and modelling of the hot compression of a TC6 titanium alloy. Materials Characterization, 49(3), 203-209. https://doi.org/10.1016/S1044-5803(02)00323-6

9. Gurevich, S.M., Zamkov, V.N., Kushnirenko, N.A. (1971) Welding of titanium alloys of VT15 type. Avtomatich. Svarka, 10, 46-50 [in Russian].

10. Santos, D.S., Bououdina, M., Fruchart, D. (2002) Structural and thermodynamic properties of the pseudo-binary TiCr2− xVx compounds with 0.0 ≤ x ≤1,2. J. of Alloys and Compounds, 340(1-2), 101-107. https://doi.org/10.1016/S0925-8388(02)00013-0

11. Poryadchenko, N.Y., Kuz'menko, M.M., Oryshych, I.V. et al. (2005) High-temperature strength of titanium alloys alloyed with silicon, aluminum and zirconium in air. Mater. Sci. 41(2), 230-236. https://doi.org/10.1007/s11003-005-0155-1

12. Datskevich, O., Kulak, L., Miracle, D. et al. (2002) Study of the effect of thermal treatment on the structure and properties of Ti-Al-Si-Zr system alloys. In: Proc. of the Intern. Conf. on Sci. for Materials in the Frontier of Centuries: Advantages and Challenges, Kyiv, Nov., 2002, 2. IPMS, Kyiv.

13. Khorev, A.I. (2010) Increase of structural strength of thermally and thermomechanically-hardened titanium alloys. Vestnik Mashinostroeniya, 5, 26-34 [in Russian]. https://doi.org/10.3103/S1068798X10050060

14. Akhonin, S.V., Severin, A.Yu., Belous, V.Yu. et al. (2017) Structure and properties of titanium alloy VT19, produced by the electron beam melting, after thermomechanical treatment. Sovrem. Elektrometall., 3, 19-24 [in Russian]. https://doi.org/10.15407/sem2017.03.04

15. Akhonin, S.V., Pikulin, A.N., Berezos, V.A. et al. (2019) Laboratory electron beam unit UE-208M. Ibid., 3, 15-22 [in Russian]. https://doi.org/10.15407/sem2019.03.03

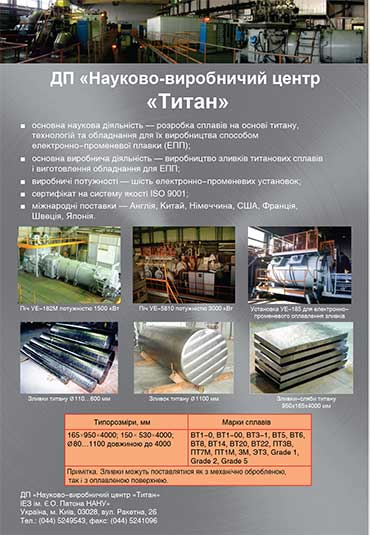

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.