| SCIENTIFIC AND TECHNICAL | |

|

ZAMKOV V.N., PRILUTSKY V.P., PETRICHENKO I.K., VRZHIZHEVSKY E.L.

and TOPOLSKY V.F. EFFECT OF THE METHOD OF FUSION WELDING ON PROPERTIES OF WELDED JOINTS IN ALLOY Ti-6Al-4V | 2 |

| Mechanical and corrosion properties of arc, electron beam and laser welded joints in alloy Ti-6Al-4V are compared, allowing for peculiarities of thermal cycles of laser welding. Susceptibility of the laser weld metal to stress corrosion cracking in an aggressive environment is found to be by an order of magnitude higher than that of the arc weld metal. Annealing of welded joints does not decrease their sensitivity to cracking. | |

|

ELAGIN V.P., SNISAR V.V., SAVITSKY M.M., GORDAN G.N., VASILIEV

V.G. and DOROSHENKO L.K. CHEMICAL AND STRUCTURAL INHOMOGENEITY IN THE ZONE OF FUSION OF LOW-CARBON STEEL WITH AUSTENITIC WELD DURING SHIELDED-GAS WELDING | 7 |

| It is shown that a poor stirring of molten metal in the weld pool is one of the causes of increasing the chemical, structural and mechanical inhomogeneity in the zone of fusion of the low-carbon steel with an austenitic weld (at a low level of its alloying). The performance of welding in nitrogen- and oxygen-containing shielding media improves the metal stirring, thus leading to the decrease in the level of inhomogeneities in the zone of fusion of the low-carbon steel with an austenitic weld. | |

|

ZVYAGINTSEVA A.V., YUSHCHENKO K.A. and SAVCHENKO V.S. EFFECT OF STRUCTURAL CHANGES IN HIGH-TEMPERATURE HEATING ON DUCTILE CHARACTERISTICS OF NICKEL ALLOYS | 13 |

| Investigation of hot ductility of alloy IN 840 proves that it has three characteristic ductility temperature ranges. Drastic fall in ductility takes place in a narrow temperature range. It results from melting of grain boundaries to form on them small amounts of the liquid films. The data of metallography and fractography obtained on welded samples show that fracture at high temperatures occurs along the boundaries of grains (dendrites) rich in alloying elements and is of the same nature as fracture of the base metal at high temperatures. | |

|

VASENIN Yu.L., ZAGREBELNY A.A., ZELNICHENKO A.T., KRIVTSUN I.V.

and SHULYM V.F. MODELLING OF THERMAL PROCESSS IN PIPING REPAIR IN SPACE | 18 |

| A mathematical model of thermal processes in welding of piping in space is proposed. Software has been developed for implementation of the above model in the computer. Detailed computer simulation of thermal processes in stainless tube brazing has been performed. Optimal geometrical parameters and conditions of the brazed joint heating are determined, as well as time and energy required for performance of brazing. | |

|

DMITRIK V.V. and SHEVCHENKO V.V. EFFECTIVENESS IN USE OF MOLTEN POOL HEAT | 24 |

| Method for estimation of the amount of the arc heat introduced into parent metal and transferred with the liquid metal flows from the head to the tail portion of the weld pool is suggested. It is shown that the efficiency in use of the molten pool heat can be increased by using an extra filler metal and selecting the optimum parameters of welding. | |

|

GONCHAROV I.A., PALTSEVICH A.P., TOKAREV V.S., VEBLAYA T.S. and

KHARCHENKO N.P. ABOUT THE FORM OF HYDROGEN EXISTENCE IN WELDING FUSED FLUXES | 27 |

| The forms of hydrogen existence in welding fused flux AN-348A were examined using the methods of IR-spectroscopy, thermogravimetry and gas chromatography. As model substances the zeolite NaA and kaolin were used. A significant difference of flux AN-348A from the zeolite is shown by a nature of a thermal hydrogen desorption. It is established that the main part of the latter is dissolved in the flux examined during the process of furnace melting in the form of a hydroxyl and removed at heating above 800 oC. | |

|

POPOV S.N. OPTIMIZATION OF CHEMICAL COMPOSITION OF DEPOSITED METAL OF COMPONENTS OPERATING UNDER THE CONDITIONS OF ABRASIVE WEAR | 31 |

| Results of planning and processing of experimental data to optimize the chemical composition of the deposited metal possessing high wear resistance are presented. The effect of carbon, boron and vanadium in ferro-chromium (13 % Cr) alloys on their resistance to the abrasive wear is determined. | |

| INDUSTRIAL | |

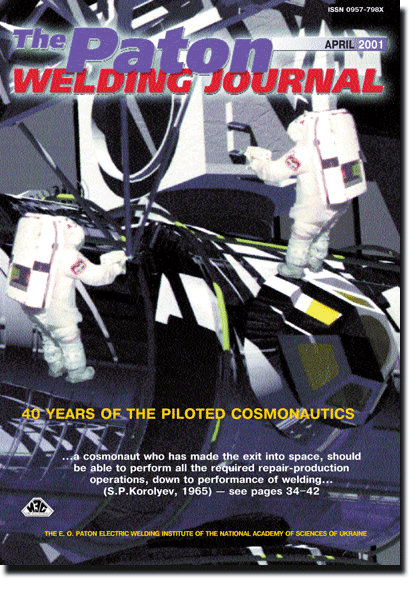

| 40 YEARS OF PILOTED COSMONAUTICS. | 34 |

|

LANKIN Yu.N. and GAVRISH S.S. DEVICE FOR PROVISION OF SAFE OPERATION OF MANUAL ELECTRON BEAM TOOL IN SPACE | 36 |

| A device for protection from the electron beam in manual electron beam welding in space is described. The device operation is based on short-term (0.002 s) probing with the electron beam of the surfaces being welded. When the distance from the gun to the surfaces being welded is increased above the working distance, the device lowers the beam power density to a safe level and (or) completely switches the beam off. | |

|

BULATSEV K.A. and BULATSEV A.A. SYSTEM OF MONITORING THE POSITION OF MANUAL ELECTRON BEAM TOOL | 39 |

| The paper deals with a system of welding tool position monitoring, based on the use of a PC and indirect information input device. The device block-diagram, operational algorithm and schematic of the actual embodiment of the sensor are given, as well as testing results. | |

|

TOCHIN V.V., YUSHCHENKO B.I., RUSINOV P.P., DEMIANENKO V.V. and

PALAMARCHUK T.E. SAFETY SYSTEM OF ELECTRON BEAM TOOL | 42 |

| One of the possible variants of ensuring the safety can be the use of "technical vision" for automatic control of aiming the beam into the working zone. A safety system is described that is based on processing the video information received from the welding zone. | |

|

PROKOFIEV A.S., PISMENNY A.S., BONDAREV V.A. and BONDAREV A.V.

INDUCTION BRAZE-WELDING OF NO-ACCESSORY T-JOINTS IN PIPES | 44 |

| Types of designs of no-accessory T-joints and methods for their manufacture are analysed. The technology for production of T-joints in thin-walled small-diameter pipes using braze-welding, as well as strength characteristics of the T-joints and their capability of preserving shape and geometrical dimensions under loading during mechanical tests are considered. | |

|

NESTERENKO N.P., SENCHENKOV I.K., CHERVINKO O.P. and DYACHENKO

S.M. DESIGNING OF MULTISTAGE WAVEGUIDES-TOOLS FOR ULTRASONIC WELDING OF THERMOPLASTIC MATERIALS | 49 |

| Method of designing multistage waveguides for ultrasonic welding of polymers and composites on a thermoplastic base has been suggested. Known and new basic configurations of waveguides, which can be used for welding at different levels with respect to the support, are considered. | |

|

NAJDA V.L., MOZZHUKHIN A.A., GETMAN V.V., PYSHNY V.M. and TOROP

V.M. INTEGRATED APPROACH IN TECHNICAL DIAGNOSTICS OF PIPELINES IN AUTOMATIC ULTRASONIC TESTING OF BUTT WELDS | 52 |

| Capabilities of modern AUT means, developed in E.O. Paton Electric Welding Institute have been considered. It is shown that since the parameters characterizing the objects of diagnostics, defects, loading conditions and mechanical properties of the materials can vary in time, an integrated approach is effective, provided computerized systems are used. | |

| BRIEF INFORMATION | |

|

PETUSHKOV V.G. and TITOV V.A. PARAMETERS OF SHOCK-WAVE LOADING USED TO RELIEVE RESIDUAL WELDING STRESSES BY EXPLOSION TREATMENT | 57 |

| Results are given on the use of methods developed for investigation of pressures and strains induced in a welded joint metal loaded by sliding detonation of a cord explosive charge to relieve residual welding stresses. It is shown that the use of the methods makes it possible to obtain sufficiently reliable results needed for theoretical description of the mechanism of relief of residual stresses by explosion treatment of welded joints. | |

(You are viewing the simplified file contents)

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.