| To 100th birthday anniversary of Professor Georgy A. Nikolaev. | 2 |

| Famous Scientist, Engineer, Teacher. | 3 |

| SCIENTIFIC AND TECHNICAL | |

| Dovbishchenko I.V., Mashin V.S., Shonin V.A. and Pashulya M.P.

Properties of overlap joints of aluminium alloys produced by consumable electrode spot arc welding. | 6 |

| Influence of the mode of consumable electrode pulsed-arc spot welding on the main geometrical parameters of welds, shear strength of weld nugget and off-centre rupture strength of the base metal have been studied in overlap joints of sheet aluminium alloys AMg6 and AD33. It is shown that maximum admissible current at minimum welding time should be used to reduce the heat input into the metal being welded and deformations of the upper sheet. Optimal values of nugget diameter have been established for different spot spacing in the overlap joint, at which the equal shear strength of the spot weld and rupture strength of the base metal are achieved. | |

| Ryabtsev I.I. and Kuskov Yu.M.

Prospects for applying phosphorus in iron-base surfacing consumables (Review). | 12 |

| Analysis of literature data on the effect of phosphorus on mechanical and service properties of steels and cast irons has been conducted. It is shown that phosphorus is a candidate alloying element for surfacing consumables intended for repair and hardening of parts operating under metal against metal friction conditions. | |

| Titov V.A., Fadeenko Yu.I. and Petushkov V.G.

Selection of optimal methods for explosion loading of welded joint based on estimation of hardness. | 17 |

| Results of investigation into the effect of explosion treatment of welded joints using elongated explosive charges on distribution of residual stresses are given. Formulae relating parameters of residual stress fields in the explosion treated welded joints to parameters characterising explosion treatment conditions are presented. | |

| Markashova L.I., Berdnikova E.N. and Khomutskaya I.I.

Link between the structure and strength properties of steel-aluminium joints made by friction and explosion welding. | 22 |

| Results of investigations of specifics of processes of structure and phase formation in joints of dissimilar metals with a limited mutual solubility (St.3 + aluminium), made by pressure welding using different temperature conditions of welding deformation (conventional and inertia friction welding and explosion welding) are presented. | |

| Khorunov V.F., Shvets V.I., Taranova T.G. and Kobzenko G.F.

Fusibility curves for alloys of the Sn-Zn-Bi system. | 26 |

| Fusibility curves and structural peculiarities of alloys of the Sn-Zn-Ni systems in a range of Sn-rich compositions were studied using differential thermal analysis. The resulting data can be employed for development of commercial Pb-free solders for soldering parts used in radio electronics. | |

| Spiridonova I.M., Sukhovaya E.V. and Pilyaeva S.B.

Wear-resistant composite coatings with fillers of Fe-B-C system. | 30 |

| Structure and abrasive wear resistance of composite coatings with a brass binder and fillers, made from alloys (Fe-B-C), containing 0-9 % B, 0-4 % C, Fe being the balance, deposited on steel components, are studied. The effect of structural and phase composition of the filler on structure and width of zones of a contact interaction forming at the interfaces of composite coatings is shown. Optimum sizes and structural composition of zones of interaction are determined which provide the higher wear resistance of the composite coatings. | |

| INDUSTRIAL | |

| Yushchenko K.A., Chekotilo L.V., Tsaryuk A.K., Ivanenko V.D., Starushchenko T.M., Kuzhel A.V., Lysov Yu.A., Kravchenko N.V., Ulianov V.I. and Gordienko V.A.

New documents for manufacture and repair of power generation equipment. | 34 |

| The list of technological instructions and process flow sheets for welding operations to be used as a guideline in manufacture, assembly and repair of power generation equipment is given. | |

| Budnik V.P.

Features of direct current straight polarity welding of aluminium alloys. | 37 |

| Papers dedicated to the process of direct polarity current welding of aluminium alloys developed by the E.O. Paton Electric Welding Institute and its commercial application are reviewed. The application field of this process has been identified, the related problems are listed and advantages are shown. | |

| Shelyagin V.D., Khaskin V.Yu., Siora A.V., Sakharnov A.V. and Goncharenko E.I.

Laser welding of thin-sheet steels using special approaches. | 39 |

| Advantages of laser welding using various technological approaches, including an additional feed of a filler wire, deposition of thin layers of flux on base metal, decrease in focal distance of the lens and application of periodic-pulse modulation of the laser beam, are considered. | |

| Makarenko N.A. and Nevidomsky V.A.

Thermal cycles in plasma-MIG surfacing. | 43 |

| Drawbacks of the technology for flux-cored wire submerged-arc surfacing of metallurgical equipment parts operating under thermal loading conditions are noted. Non-uniform distribution of alloying elements across the deposited bead section leads to decrease in strength of the roll-type continuous casting machines. Peculiarities of heat input in plasma-MIG surfacing provide uniform distribution of the surfacing alloy components in the first layer. | |

| Levchenko O.G. and Mashin V.S.

Sanitary-hygienic characteristic of process of consumable electrode inert-gas welding of AMg6 aluminium alloy. | 46 |

| Results of investigation of the content of harmful elements in air in inert-gas welding of aluminium alloys are presented. Recommendation are given on protection of welders' respiratory organs. | |

| BRIEF INFORMATION | |

| Kiselevsky F.N., Pritula S.I. and Dolinenko V.V.

System of welding torch following along the butt using a TV sensor. | 49 |

| Architecture of system for the butt following using a laser-TV sensor is considered. Hardware components of a pilot model of this system are described and their technical characteristics are given. | |

| Korotynsky A.E.

Multifunctional welding inverter made by two-module design. | 50 |

| Design of a multifunctional welding inverter is described which is based on a two-module scheme. A module based on a single-step bridge converter was selected as the inverter core. Several design variants for MMA, TIG and MIG/MAG welding are described, as well as for air-plasma cutting, based on a two-module structure. | |

| Device "Paton PPR-200" for air-plasma cutting of metals. | 53 |

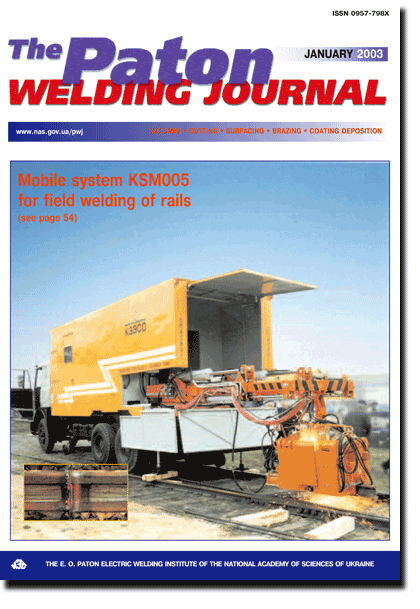

| Welding Mobile Complex KSM 005. | 54 |

(You are viewing the simplified file contents)

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.