| SCIENTIFIC AND TECHNICAL | |

| Paton B.E., Shejko P.P., Zhernosekov A.M. and Shimanovsky Yu.O. Stabilization of the process of consumable electrode pulse-arc welding. | 2 |

| Developed systems of automatic stabilization of the process of consumable electrode pulse-arc welding (CEPAW) are described, allowing stabilization of mean values of arc voltage and welding current, under the impact of disturbances. This leads to lowering of the probability of porosity and lack-of-fusion in Al-Mg alloys, decrease in spattering and sputtering, as well as stabilization of the width of welds in CEPAW of carbon steels. | |

| Makhnenko V.I., But V.S., Velikoivanenko E.A., Rozynka G.F. and Pivtorak N.I. Estimation of permissible sizes of welds for mounting T-joints and sleeves on active main pipelines. | 6 |

| Considered is the effect of geometric sizes of pipelines, T-joints and sleeves on permissible sizes of the welds, allowing for variations in the working pressure in a pipeline, as well as variants of a technology for mounting of sleeves (T-joints) without interruption of operation of the pipeline. | |

| Pokhmursky V.I., Student M.M., Dovgunyk V.M., Sidorak I.I., Kuskov Yu.M. and Ryabtsev I.I. Structure and tribotechnical characteristics of coatings produced by electric arc metallizing using flux-cored wires. | 12 |

| Effectiveness of application of electric arc metallizing for restoration of worn-out parts of the machines is outlined. Adding of different components, ferrophosphorus in particular, into the charge of flux-cored wires, can decrease significantly the coefficient of friction and wear of coatings in metallizing and increase the service life of the as-restored parts. | |

| Grabin V.F., Golovko V.V., Solomijchuk T.G., Goncharenko E.I. and Kostin V.A. Analysis of structural state of weld metal produced by using welding wires of the ferritic-pearlitic grade. | 17 |

| It is shown that alloying of low-carbon weld metal with manganese leads to formation of a small amount of pearlite and up to 40-50 vol.% of acicular ferrite in it. Owing to a high acicular ferrite content, weld metal of the Fe-Mn-Mo-Ni alloying system is characterised by a higher level of mechanical properties than weld metal of the Fe-C-Mn alloying system. | |

| Efimenko N.G. Integrated evaluation of effect of yttrium on properties of steel welds. | 23 |

| The refining, modifying and alloying role of yttrium in the metal of low-alloyed welds, depending on its concentration, was experimentally confirmed. Yttrium influence in weld metal is most favourably manifested for its ductile properties and toughness in case of proceeding of the refining and modifying effects. | |

| INDUSTRIAL | |

| Rossoshinsky A.A., Kislitsyn V.M., Musin A.G. and Pavlyuk S.P. Microsoldering methods. | 27 |

| Several processes of welding and soldering are considered, which were developed at PWI in 1965 -- 1985 and are used in the technologies of mass production of discrete semiconductor devices and integral microcircuits. They were not widely described in publications earlier for certain reasons. | |

| Vanzhula T.V., Zamkov V.N. and Prilutsky V.P. Improving in wear resistance of parts of titanium alloys (Review) | 30 |

| Methods for improving wear resistance of titanium alloys, including thermochemical treatment, deposition of galvanic coatings, flame and plasma spraying, laser and electric-spark surface alloying and brazing, are reviewed. Efficiency of their application is assessed. It is shown that the most promising method is argon-arc surfacing, requiring development of new filler materials. | |

| Pulka Ch.V. Hardfacing the working components of tillage and harvesting agricultural machinery (Review). | 35 |

| The paper presents a review of the existing methods of hardfacing the tools of agricultural machinery and considers their advantages and drawbacks. | |

| Levchenko O.G., Metlitsky V.A., Ryabtsev I.A. and Grishchenko S.A. Sanitary-hygienic evaluation of flux-cored wires for electric arc surfacing. | 41 |

| Results of investigation of chemical composition and level of evolution of welding aerosols entering the air of working zone in flux-cored wire submerged arc and open arc surfacing are presented. Recommendations are suggested for protection of workers-welders and environment from welding aerosols. | |

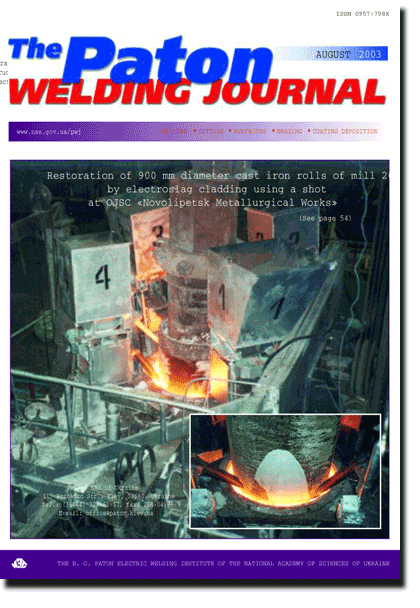

| Nevidomsky V.A., Krasilnikov S.G., Panin A.D., Gerashchenko V.Ya. and Shapovalov K.P. Experience in welding of copper-steel moulds at NKMZ Company. | 46 |

| Specialized fixture, equipment and technological procedures are presented which make it possible to manufacture large-sized copper metal structures, such as moulds for electroslag cladding of composite mill rolls. | |

| BRIEF INFORMATION | |

| Brodovoj V.A., Mikheev P.P. , Knysh V.V., Gushcha O.I., Kuzmenko A.Z. and Labur T.M. Effectiveness of fatigue crack retardation by the field of compressive residual stresses. | 49 |

| Methods of fatigue crack retardation are studied, which are based on inducing compressive residual stresses in front of crack tips. Experiments were performed on specimens of aluminium alloy D16AT and steel St3sp (killed) with inducing residual stresses by a spot argon-arc surfacing and local heating. It is shown that inducing residual stresses in front of a crack at the level of just 0.3-0.5-s-y of those of the base metal increases the life of a sample by an order of magnitude or more. | |

| Kisilevsky F.N. and Shapovalov E.V. Determination of optimum length of an illuminator in technical vision systems for arc welding. | 51 |

| The paper gives the main technical characteristics of the existing optical sensors in systems of technical vision for arc welding. Spectral characteristics of welding arc are studied to determine the local minimums of luminosity in the wave length range from 500 to 1100 nm. Ranges of wave lengths of illuminator operation are recommended to increase the signal-to-noise ratio of arc welding. | |

(You are viewing the simplified file contents)

Sorry, the PDF of this issue is not yet available

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.