| Welding production of «Uralmashzavod». Stages of formation and development | 2 |

| SCIENTIFIC AND TECHNICAL | |

| Polyakov S.G., Rybakov A.A. and Nyrkova L.I. Computer programs for designing effectiveness of pipeline protection by the method of non-linear polarization | 5 |

| A computer program has been developed for calculation of electrochemical parameters and its performance has been verified in the laboratory and in the route, when testing a gas pipeline, using an electrochemical microprocessor system (ECMS). Obtained data on the rate of soil corrosion of pipeline metal correlate in a satisfactory manner with that of mass measurements. Possibility of evaluation of the rate of residual corrosion of pipeline metal in a coating defect using ECMS and developed program, allows an objective assessment of the degree of pipeline protection and taking a well-grounded decision on the sequence of repair of pipeline section with damaged insulation. | |

| Bushma A.I., Vasenin Yu.L. and Krivtsun I.V. Modelling of the process of laser spraying of ceramic coatings allowing for scatter of the laser beam by spray particles | 10 |

| Mathematical model was developed for computer simulation of movement and heating of particles of finely dispersed ceramic materials under conditions of laser spraying of coatings. Scatter and absorption of the laser beam by the whole of the particles were allowed for in estimation of local values of the intensity of radiation along the path of movement of an individual particle. The paths, velocities, spatial distribution and temperature fields of fine SiO2 particles under conditions of laser spraying using CO2-laser were calculated. It is shown that powder consumption has a substantial effect on distributed and integral characteristics of the laser beam, as well as on the thermal state of the spray particles. | |

| INDUSTRIAL | |

| Kornienko A.N. and Zhadkevich A.M. Development and application of brazed lattice and honeycomb structures in aircraft engineering (Retrospective review) | 15 |

| The paper presents the background of emergence, development and application of lattice and honeycomb structures of flying vehicles. An abrupt improvement of the quality of structural alloys and aircraft and missile manufacturing technologies occurred in the second half of the XX century. In view of the increasing sophistication of the structures and difficulties of applying other technologies, brazing is becoming the most promising joining process. Brazing filler metals and technologies have been developed, which ensured high performance of aircraft and space vehicles. /font> | |

| Tkachenko A.N. and Voskresensky A.S. Application of arc spot welding in fabrication of car bodies | 22 |

| Application of arc spot welding for manufacture of side walls of car bodies for diesel trains, and, in particular, joining stiffeners to sheathing in the cars are considered. Optimum welding conditions for spot welds have been selected, quality of overlap welded joints has been assessed, and strength tests have been conducted. /font> | |

| Ignatchenko P.V. and Bugaj A.I. 15 years of Association «Electrode» and analysis of state-of-the-art in production of welding consumables in the CIS countries during 2000--2004 | 24 |

| Main areas of activity of Association «Electrode» in the CIS countries during the last 15 years are described. The rates of development of production of welding consumables and trends in improvement of quality and competitiveness are shown. /font> | |

| Marchenko A.E. Technology as an object and tool of quality management in welding electrode production | 29 |

| Quality and price are the key components of market competitiveness of electrode products. Technology of welding electrode manufacturing is a complex multi-operation process, having a multitude of potential disturbance sources that should be suppressed to achieve the required quality of products at an affordable price. The article analyses traditional engineering-technical approaches, which should be applied in combination with management approaches used by our electrode manufacturers in practice in keeping with recommendations of ISO 9000:2000. | |

| Kucherova M.I., Belov Yu.M., Rantsev A.A. andArsyukov D.V. Development of electrodes with high welding-technological properties for surfacing | 37 |

| Data are given on development of a series of new generation electrodes designed for surfacing the sealing surfaces of fittings, working surfaces of bearings, cutting edges, parts exposed to highly aggressive media in operation. /font> | |

| Baranov A.V., Brusnitsyn Yu.D., Kashchenko D.A. and Sokolov A.A. Improvement of technologies for welding electrode manufacture | 38 |

| Experience of using mineral alloys in electrode coatings, containing aluminium in the form of alumina, kaolin or nepheline is described. It is shown that additions of mineral alloys decrease the reactivity of powder components of electrode coatings. /font> | |

| Orlov L.N., Golyakevich A.A., Titarenko V.I. and Peleshko V.N. Renovation surfacing of metallurgical and mining equipment using flux-cored wires | 40 |

| The paper gives information on flux-cored wires produced by TM.VELTEK, Ltd. and experience of their application in renovation of the parts and mechanisms in metallurgical and mining industries. /font> | |

| Gezha V.V., Bishokov R.V., Shekin S.I. and Melnikov P.V. Advanced welding consumables for fabrication of structures from cold-resistant steels in different industries | 45 |

| The paper gives the characteristics of new electrodes, ceramic flux and flux-cored wire for welding cold-resistant steels of different strength levels. | |

| BRIEF INFORMATION | |

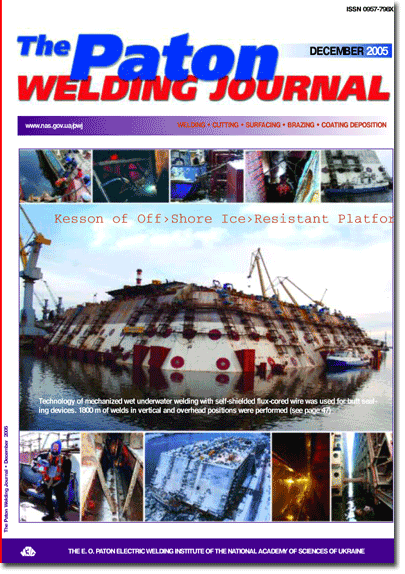

| Kononenko V.Ya. Application of the technology of mechanized underwater welding in construction of off-shore ice-resistant platform «Prirazlomnaya» | 47 |

| Specifics of mechanized underwater welding of butt sealing devices for off-shore ice-resistant stationary platform using flux-cored wire PPS-EK1 is described. | |

| Eryomin E.N. Application of a combined electrode in electroslag welding of thin materials | 48 |

| It is suggested that joints of a small length and thickness should be made by electroslag welding using a combination of consumable and nonconsumable electrodes. Technological peculiarities of the above welding process are described, and results of investigation of weld metal produced in welding of KhN38VT alloy are given. Advantages of the new welding technology are shown. | |

| Theses for scientific degree | 50 |

| NEWS 56 | |

| 70th Birthday of Prof. K.A. Yushchenko | 52 |

| Plasma cutting of metals under water | 54 |

| Developed at PWI | 39, 55 |

| Index of articles for TPWJ'2005, Nos. 1-12 | 59 |

| List of authors | 67 |

(You are viewing the simplified file contents)

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.