| 2015 №12 (05) |

DOI of Article 10.15407/tpwj2015.12.06 |

2015 №12 (07) |

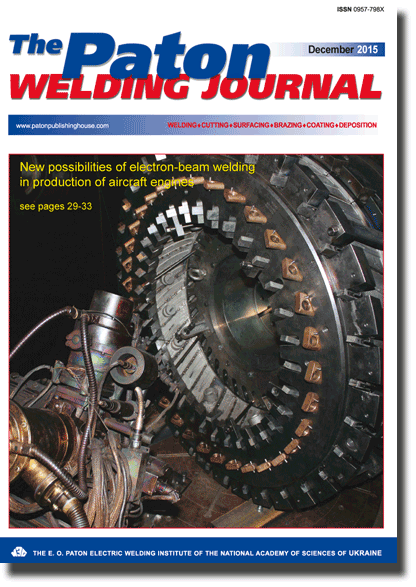

The Paton Welding Journal, 2015, #12, 29-33 pages

Electron beam welding of medium-pressure chamber of gas turbine engine

V.M. Nesterenkov1, L.A. Kravchuk1, Yu.A. Arkhangelsky1, I.A. Petrik2 And Yu.A. Marchenko2

1E.O. Paton Electric Welding Institute, NASU. 11 Bozhenko Str., 03680, Kiev, Ukraine. E-mail: office@paton.kiev.ua

2Company «Motor-Sich». 15 Motorostroiteli Ave., 69068, Zaporozhie, Ukraine. E-mail: motor@motorsich.com

Abstract

Investigations were performed in order to develop the technology of manufacturing all-welded outer part of front case of GTE medium-pressure chamber, and schemes of welding the inner and outer butt welds of posts were selected, providing defect-free formation of face and root weld beads at through-thickness penetration of cast titanium a-alloy VT5L of 5-26 mm thickness in one pass. System of computer control of the process of EBW in UL-209M machine allows performing in one process cycle cleaning of the butt vicinity from remains of contamination and oxides, using low-power electron beam focused on the metal surface, as well as spot, short and continuous tack welds. Rotators with vertical and horizontal axes of rotation are provided for positioning, fixing and rotation of the item relative to electron beam gun. Programs for EBW given in the form of tables, assign the values of coordinates of points of each path section, to which it is necessary to move, values of welding and focusing currents, process scan amplitudes, as well as speed of displacement in a given section. At constant welding speed 12 mm/s, values of welding current and focusing current in the transition points of the change of working distance and thickness of edges being welded were varied by a linear law, that ensured formation of the weld face and root beads without undercuts or depressions along the entire butt length. 15 Ref., 7 Figures.

Keywords: electron beam welding, electron beam, through-thickness penetration, weld face and root beads, variable thickness, welding scheme, porosity, macrostructure, computer control, videocontrol device, welding program

Received: 13.07.15

Published: 21.01.16

References

- Pavlenko, V.N., Rudnev, Yu.T., Barinov, V.V. et al. (1989) Electron beam welding of GTE multisection wheel from titanium alloy. In: Abstr. of All-Union Sci.-Techn. Conf. on Electron Beam Welding in Mechanical Engineering (Nikolaev, Ukraine, 1989), 13-14.

- Gejkin, V.A., Poklad, V.A. (2001) Welded joints in aircraft engines. Tekhnologiya Metallov, 1, 9-14.

- Lobanov, L.M., Pivtorak, V.A., Zadery, B.A. et al. (1993) Residual stresses in electron beam welded elements of gas turbine engine rotor structures. In: Proc. of Conf. on EBW, Book 2, 57-61. Moscow: TsRDZ.

- Imamura, T. (1999) Current states and trend of applicable material technology for aerospace structure. J. JILM, 1(7), 302-309. https://doi.org/10.2464/jilm.49.302

- Paton, B.E., Nazarenko, O.K., Nesterenkov, V.M. et al. (2004) Computer control of electron beam welding with multi-coordinate displacements of the gun and workpiece. The Paton Welding J., 5, 2-5.

- Kravchuk, L.A. (2010) Elimination of undercuts in EBW with complete and incomplete penetration. Ibid., 6, 22-25.

- Nesterenkov, V.M. (2003) Special features of capillary waves in the vapour-gas channel in electron beam welding of thick metal. Ibid., 4, 7-12.

- Nazarenko, O.K., Kajdalov, A.A., Kovbasenko, S.N. et al. (1987) Electron beam welding. Kiev: Naukova Dumka.

- Blakely, P.Y., Sanderson, A. (1984) The origin and effect of magnetic fields in electron beam welding. Welding J., 1, 42-49.

- Frits, D. (1988) Electron beam welding today. In: Proc. of Int. Conf. on Electron Beam Technologies (Varna, 31 May-4 June, 1988), 1048-1063.

- Sayegh, G. (1986) State of the art of high energy density beam welding: Houdremont lecture. Tokyo: IIW.

- Shida, T., Kita, H., Okamura, H. et al. Effects of welding parameters and prevention of defects in deep penetration EBW of heavy section steel. IIW Doc. IV, 239-78.

- Stocker, G. (1974) Erfahrungen beim Elektronenstrahlschweissen dick wandiger Bauteile aus der Titanlegierung Ti6Al4V gegliht. Schweissen und Schneiden, 3, 91-93.

- Nudelman, Ya.B., Zadery, B.A. (1988) Weld formation in electron beam welding of titanium alloy of up to 25 mm thickness. Avtomatich. Svarka, 5, 29-30.

- Anderl, P., Scheffels, W. (1992) Process control for electron beam welding. Welding in the World, 5/6, 138-144.

Suggested Citation

V.M. Nesterenkov, L.A. Kravchuk, Yu.A. Arkhangelsky, I.A. Petrik And Yu.A. Marchenko (2015) Electron beam welding of medium-pressure chamber of gas turbine engine. The Paton Welding J., 12, 29-33.The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.