Access for download PDF files for subscribers and for reviewers of scientometric bases.

Organization: Elsevier for content access(PDF files of journals released before 2024 are available for download from the website's archives))

Organization: Elsevier for content access(PDF files of journals released before 2024 are available for download from the website's archives))

| 2022 №04 (02) |

DOI of Article 10.37434/sem2022.04.03 |

2022 №04 (04) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2022, #4, 15-19 pages

Influence of external longitudinal magnetic field on formation of ESM ingot surface

V.B. Porokhonko, I.V. Protokovilov, D.A. Petrov

E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: office@paton.kiev.ua

Abstract

The influence of constant and pulsed longitudinal magnetic fields with induction В = 0.16…0.30 T on the quality of outer surfaces of titanium ingots of 85 mm diameter, produced by ESM process, was studied. It is shown that alongside the positive effects of magnetic field action, manifested in increase of ESM process efficiency, improvement of chemical homogeneity of the ingots, and refinement of their crystalline structure, application of magnetic fields leads to deterioration of the quality of formation of the ingot side surface. Here, the degree of surface deterioration depends on magnetic field induction and duration of its pulses. It is found that application of pulsed magnetic fields to leads to deterioration of the ingot surfaces to a smaller extent than application of constant magnetic fields. Described are the mechanisms which negatively affect the quality of ingot surface formation under the impact of the longitudinal magnetic field. They consist in removal and solidification of electrode drops near the mould walls and periodical change of the skull crust thickness as a result of the slag and metal pool melt vibration. Ref. 8, Fig. 5.

Keywords: electroslag remelting; longitudinal magnetic field; pulsed field; ingot; surface; titanium

Received 29.09.2022

References

1. Dudko, D.A., Rublevsky, I.N. (1960) Electromagnetic stirring of slag and metal pool in electroslag process. Avtomatich. Svarka, 9, 12-16 [in Russian].2. Trochun, I.P., Chernysh, V.P. (1965) Magnetic control of crystallization in ESR. Svarochn. Proizvodstvo, 11, 3-5 [in Rusian].

3. Paton, B.E., Medovar, B.I., Us, V.I., Tomilenko, S.V. (1989) Development and examination of methods of control of ESR crystallizing ingot structure by magnetic field superposition. Problemy Spets. Elektrometallurgii, 4, 3-7 [in Russian].

4. Kompan, Ya.Yu., Protokovilov, I.V. (2002) Some technological aspects of magnetically-controlled electroslag melting (MEM) of titanium alloys. Int. Sci.-Tech. Conf. on Special Metallurgy: Yesterday, Today, Tomorrow (Ukraine, Kyiv, 8-9 October 2002). 256-262.

5. Kompan, Ya.Yu., Nazarchuk, A.T., Protokovilov, I.V. (2007) Towards the problem of intensification of electromagnetic action in magnetically-controlled electroslag melting of titanium alloys. Advances in Electrometallurgy, 4, 3-7.

6. Kompan, Ya.Yu., Nazarchuk, A.T., Protokovilov, I.V., Petrov, D.A. (2012) Possibilities of application of pulsed electromagnetic effects in electroslag processes. Ibid., 2, 8-13.

7. Protokovilov, I., Shapovalov, V., Porokhonko, V. et al. (2021) Effect of the longitudinal magnetic field on the droplets evolution during electroslag remelting process. Magnetohydrodynamics, 57(4), 559-568. https://doi.org/10.22364/mhd.57.4.10

8. Protokovilov, IV., Porokhonko, V.B. (2017) Physical modeling of electrode metal drop transfer in ESM with superposition of pulsed magnetic fields. Suchasna Elektrometal., 3, 9-13 [in Ukrainian]. https://doi.org/10.15407/sem2017.03.02

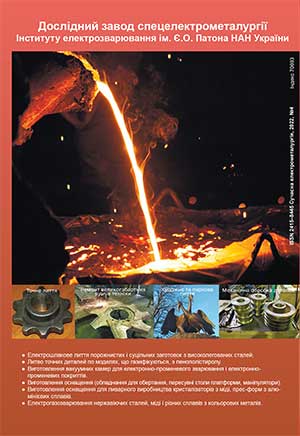

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.