| 2020 №01 (06) |

DOI of Article 10.37434/sem2020.01.01 |

2020 №01 (02) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2020, #1, 8-13 pages

Thermodynamics of interactions and physical properties of slags of 30CaF2/30CaO/30Al2O3 (SiO2, MgO) system at electroslag remelting

L.O. Lisova1, G.P. Stovpchenko2, I.O. Goncharov1, Ia.V. Gusiev1, L.B. Medovar1

1E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: office@paton.kiev.ua

2PC «ELMET-ROLL». P.O. Box 259, 03150, Kyiv, Ukraine. E-mail: office@elmet-roll.com.ua

Abstract

Thermodynamic calculations of the equilibrium content of components in the gas–slag–metal system were performed for the conditions of electroslag remelting of 15Cr11MoV steel in inert gas atmosphere (argon) under 30CaF2/30CaO/30Al2O3 slags with various SiO2 (1; 2,5; 4 wt.%) and MgO (3; 6; 12 wt.%) content. Appearance of MnO (0.04…0.07 wt.%) and FeO (0.01…0.02 wt.%) oxides in the equilibrium composition of the system indicates a minor oxidizing effect caused by the slag on the metal. The element content in the metal still remains within the margins of standard requirements to 15Cr11MoV steel. According to the results of viscosity and electrical conductivity measurements, a new slag composition has been proposed (ANF-39: 29…35 % CaF2, 30…36 % Al2O3, 27…32 % CaO, 2…4 % MgO, 1…3 % SiO2, TC 20.5-05416923-112: 2015), which has a wider solidification range and lower conductivity than the foreign analogue ESR 2015. The latter is a prerequisite for the reduction electricity consumption during remelting. Ref. 17, Tabl. 2, Fig. 2.

Keywords: electroslag remelting; thermodynamics of gas–slag–metal interaction; viscosity; electrical conductivity; energy-efficient slag

Received 4.02.2020

References

1. Mevovar, B.I., Tsykulenko, A.K., Shevtsov, V.L. et al. (1986) Metallurgy of electroslag process. Kiev, Naukova Dumka [in Russian].2. Medovar, B.I., Shevtsov, V.L., Martyn, V.M. et al. (1988) Electroslag crucible melting and pouring of metal. Ed. by B.E. Paton. Kiev, Naukova Dumka [in Russian].

3. Medovar, L.B., Stovpchenko, A.P., Lisova, L.A., Dgiang J. (2012) Modern requirements to processes and slags of electroslag remelting. Metallurg. i Gornorudnaya Promyshlennost, 7, 297–301 [in Russian].

4. GOST 30756–2001: Fluxes for electroslag technologies. General specifications.

5. Selection of optimal flux — earnest of success in electroslag remelting (ESR). Wacker Group, Electroflux: https://www.wacker.com/h/medias/6321-RU-final-0416.pdf (appl. date 22.01.2020) [in Russian].

6. TU U 20.5-00186520-126:2018: Fused fluxes PAT NZF. Specifications: https://www.nzf.com.ua/files/production/%D0%A2%D0%A3%20%D0%A3%2020.5-00186520-126-2018.pdf

7. Stovpchenko, G., Medovar, L., Lisova, L. et al. (2012) Features of slag–metal interaction at electroslag remelting of heavy ingot. In: Proc of the 9th Int. Conf. Molten Slags, Fluxes and Salts, MOLTEN12 (Beijing, China, May 27–30, 2012), 158–159.

8. Stovpchenko, A.P., Medovar, L.B., Lisova, L.A. et al. (2012) Peculiarities of physical-chemical interactions in metal-slaggas system in electroslag remelting. Sovrem. Elektrometall., 3, 3–7 [in Russian].

9. Stovpchenko, G., Medovar, L., Gusiev, Ia., Lisova L. (2015) Novel physicochemical model of the electroslag remelting process in protective gases in application to manufacturing of a large ingot of superalloys. In: Proc. of the 2015 Int. Symp. on Liquid Metal Processing & Casting, LMPC2015 (Leoben, Austria, Sept. 20–24, 2015), 219–224.

10. Gusiev, Ia., Lisova, L., Stovpchenko, G. et al. (2016) Physico- chemical approaches for new slag evaluation for ESR of superalloys. In: Proc. of Medovar Memorial Symp., MMS100 (Kyiv, Ukraine, June 7–10, 2016), 128–131.

11. Lisova, L.O., Stovpchenko, G.P. Medovar, L.B., Petrenko, V.L. (2017) Effect of slag consumption in ESR on metal composition and process technological parameters. Sovrem. Elektrometall., 2, 3-10 [in Ukrainian]. https://doi.org/10.15407/sem2017.02.01

12. Stovpchenko G., Lisova L., Medovar L. et al. (2018) Electroslag remelting for low oxygen metal manufacturing. In: Proc. of 7th Int. Congress on Science and Technology of Steelmaking, ICS2018. The Challenge of Industry 4.0 (Venice, Italy, 13–15 June, 2018), 1–10.

13. Duckworth, W.E., Hoyle, G. (1969) Electro-slag refining. London, Chapman & Hall.

14. Latash, Yu.V., Medovar, B.I. (1970) Electroslag remelting. Moscow, Metallurgiya [in Russian].

15. HSC Chemistry 9. Outotec. https://www.outotec.ru/products-and-services/technologies/digital-solutions/hsc-chemistry/ (appl. date 20.01.2020).

16. (1982) Device for measurement of electroconductivity of melted slag. USSR author’s сert. 957081, Int. Cl. 3 G 01 N 27/02, No. 2961082/18-25 [in Russian].

17. (1979) Rotary viscosimeter. USSR author’s cert. 667867, Int. Cl. 2 G 01N 11/14, No. 2564858/18-25 [in Russian].

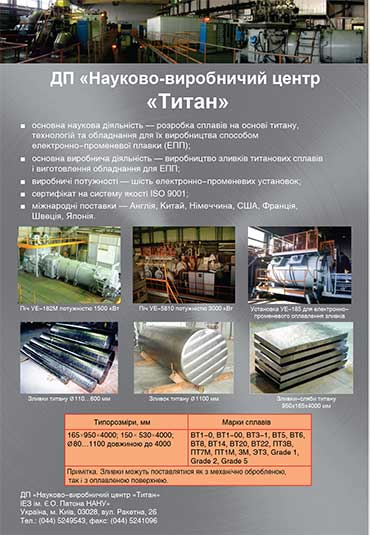

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.