| 2020 №03 (03) |

DOI of Article 10.37434/sem2020.03.04 |

2020 №03 (05) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2020, #3, 30-34 pages

xBeam 3D Metal Printing technology on the path to industrial production

D.V. Kovalchuk, V.G. Melnik, I.V. Melnik, B.A. Tugai

PJSC «SPA «Chervona Hvylia». 28 Dubrovytska Str., 03150, Kyiv, Ukraine. E-mail: info@xbeam3d.comPJSC «SPA «Chervona Hvylia». 28 Dubrovytska Str., 03150, Kyiv, Ukraine. E-mail: info@xbeam3d.com

Abstract

The possibility of introduction of a new electron beam technology of adaptive manufacturing xBeam 3D Metal Printing into industry was studied. The ability to produce a net-shape blank, using xBeam 3D Metal Printing adaptive manufacturing is demonstrated, and economic advantages of the proposed technology application over the traditional methods of metal product manufacturing are substantiated. Ref. 16, Tabl. 1, Fig. 7.

Keywords: electron beam technology; additive manufacturing; 3D printing; metal; titanium; properties; depositionВивчено питання можливості впровадження нової електронно-променевої технології адитивного виробництва xBeam 3D Metal Printing в промисловість. Продемонстровано можливість виготовлення заготовки, близької за формою до кінцевого виробу, з використанням адитивного виробництва xBeam 3D Metal Printing та обґрунтовано показано економічні переваги використання запропонованої технології перед традиційними методами виготовлення металевих виробів. Бібліогр. 16, табл. 1, рис. 7.

Ключові слова: електронно-променева технологія; адитивне виробництво; 3D друк; метал; титан; властивості; осадження

Received 27.07.2020

References

1. (2013) Additive manufacturing. A game changer for the manufacturing industry? Roland Berger Strategy Consultants GmbH. Additive manufacturing market outlook. Value chain - Market size - Key players - Business models.2. (2019) 3D printing: hype or game changer? A Global EY Report 2019.

3. (2020) Metal additive manufacturing. The AMPOWER Report 2020.

4. Wohlers Report 2020. 3D Printing and additive manufacturing state of the industry annual worldwide progress report. ISBN 978-0-9913332-3-3.

5. Norsk titanium to deliver the world`s first FAA-approved, 3D-printed, structural titanium components to boeing. Business wire. https://www.businesswire.com/ news/home/20170410005330/en/Norsk-Titanium-Deliver-World%E2%80%99s-FAA-Approved-3D-Printed-Structural

6. Lockheed m. (2018) 3D prints large titanium domes for satellite fuel tanks. Sarah saunders. Jul 12, 2018, 3D printing, aerospace 3D printing, metal 3D printing. https://3dprint.com/219196/lockheed-martin-fuel-tank-domes/

7. chaplais C. (2016) Challenges to a wider adoption of additive manufacturing in the industry. Manufacturing transformation blog. http://www.apriso.com/blog/2016/07/7-challenges-toa-wider-adoption-of-additive-manufacturing-in-the-industrypart-1/

8. (2015) The status, challenges, and future of additive manufacturing in engineering. Computer-Aided Design, 69, 65-89. https://doi.org/10.1016/j.cad.2015.04.001

9. Sand M. (2019) The TRUE economics of metal additive manufacturing: What you need to know to succeed. 3D Printing, Apr. 23. https://3dprint.com/242023/the-true-economics-ofmetal-additive-manufacturing-what-you-need-to-know-tosucceed/

10. (2020) The 3 reasons your 3D printed parts are so expensive. 3D printing. Team blueprint. March 3. https://3dprint.com/264099/the-3-reasons-your-3d-printed-parts-are-so-expensive/

11. ISO/ASTM 52900:2015 (ASTM F2792). Additive manufacturing general principles - terminology.

12. AMS 4999.

13. AMS 7004.

14. Method of manufacturing of 3D objects and device for its realization. Ukraine, Pat. 112682 [in Ukrainian]

15. Kovalchuk D., Melnyk V., Melnyk I., Tugai B. (2016) Prospects of application of gas-discharge electron beam guns in additive manufacturing. Electrotechnic and Electronic (E+E), 5−6, 36-42.

16. Makhnenko, O.V., Milenin, A.S., Velikoivanenko, E.A. et al. (2017) Modelling of temperature fields and stress-strain state of small 3D sample in its layer-by-layer forming. The Paton Welding J., 3, 11-19. https://doi.org/10.15407/as2017.03.02

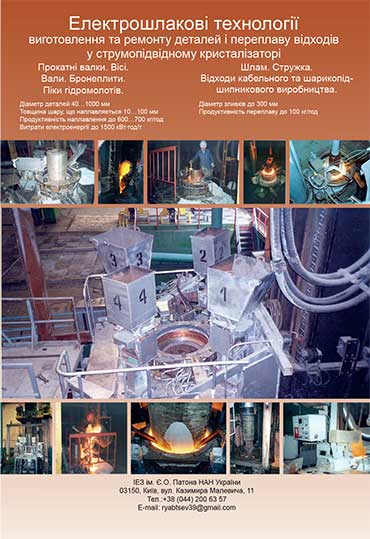

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.