| 2021 №03 (07) |

DOI of Article 10.37434/sem2021.03.08 |

2021 №03 (01) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2021, #3, 49-57 pages

Тhe processes of structure formation during directional crystallization of heat-resistant intermetallic alloy of Tial system and their influence on increase of material plasticity

N.V. Piskun

E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., Kyiv, 03150, Ukraine. E-mail: office@paton.kiev.ua

Abstract

The paper presents the results of studying the processes of structure formation in a heat-resistant intermetallic alloy of titanium-aluminium system at directional crystallization by the method of induction crucibleless zone melting and their influence on the mechanical properties. Advantages of directional crystallization of the intermetallic alloy by the method of crucibleless zone melting over other processing methods were determined. It is shown that application of this method allows obtaining the optimal structure and properties of the ingot without application of gasostatic isothermal pressing or multistep heat treatments. The principles and purposes of microalloying of TiAl system (Nb, Zr, Cr) and mechanism of the influence of each alloying element on the alloy properties have been analyzed. The processes of structure formation were studied and features were determined of phase transformations of Ti–44Al–5Nb–3Cr–1.5Zr alloy, taking place during induction crucibleless zone melting. It was proved that the developed technological process of induction crucibleless zone melting of β-stabilized intermetallic Ti–44Al–5Nb–3Cr–1.5Zr alloy ensures directional crystallization, refinement of the intermetallic grain size and allows controlling the ingot structure. The optimum phase balance, submicron interlamellar spacing and predominant orientation of the lamels along the temperature gradient are controlled by melting process parameters. Results of mechanical testing at room and high temperatures are given. These results are compared with the results of initial material testing and their compliance with the requirements for industrial application of such alloys in aircraft industry is demonstrated. It is shown that application of directional solidification at induction crucibleless zone melting promotes formation of a specific microstructure that has a positive effect both on plasticity and heat-resistance of the material, and leads to an essential increase of the modulus of elasticity. Ref. 15, Tabl. 3, Fig. 6.

Keywords: intermetallics; crucibleless zone melting; directional crystallization; structure; mechanical characteristics; modulus of elasticity; elongation

Received 01.07.2021

References

1. Fritz Appel, Jonathan David Heaton Paul, Michael Oehring John (2011) Gamma titanium aluminide alloys: Science and technology. Wiley & Sons. https://doi.org/10.1002/97835276362042. Kartavykh, A.V., Asnis, E.A., Piskun N.V. et al. (2015) Microstructure and mechanical properties control of γ-TiAl(Nb, Cr, Zr) intermetallic alloy by induction float zone processing. J. Alloys Compd., 643,182-186. https://doi.org/10.1016/j.jallcom.2014.12.210

3. Iliin, A.A., Kolachev, B.A., Polkin, I.S. (2009) Titanium alloys. Composition, structure, properties: Refer. Book. Moscow, VILS-MATI [in Russian].

4. Nochovnaya, N.A., Panin, P.V., Alekseev, E.B., Novak, A.V. (2015) Structure-phase composition regularities in titanium alloys based on otho and gamma aluminides upon thermomechanical treatment thereof. Vestnik RFFI, 85(1),18-26 [in Russian].

5. Clemens, H, Mayer, S. (2013) Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Advanced Engineering Materials, 15, 191-215. https://doi.org/10.1002/adem.201200231

6. Demenyuk, A.O., Ganeev, A.A., Demenyuk, O.B. et al. (2014) Selection of alloying elements for alloys based on titanium aluminides, Vestnik YuUrGY. Seriya Metallurgiya, 3, 95-102 [in Russain].

7. Kartavykh, A.V., Tcherdyntsev, V.V., Gorshenkov, M.V. et al. (2013) Tailored microstructure creation of TiAl-based refractory alloys within VGF solidification. Materials Chemistry and Physics, 141, 643-650. https://doi.org/10.1016/j.matchemphys.2013.05.037

8. Povarova, K.B., Bannykh, O.A. (1999) Principles of development of structural alloys based on intermetallides. Pt 1. Materialovedenie, 2, 27-33 [in Russian].

9. Povarova, K.B., Antonova, A.V., Kazanskaya, N.K. (2004) Regularities of interaction between titanium aluminides and alloying elements and interstitial phases as the base of selection of thermally stable alloys and composites. Perspektivnye Materialy, 5, 5-15 [in Russian].

10. Toshimitsu Tetsui (2002) Development of a TiAl turbocharger for passenger vehicles. Mater. Sci. and Engin.: A, 329-331, 582-588. https://doi.org/10.1016/S0921-5093(01)01584-2

11. Asnis, E.A., Piskun, N.V., Statkevich, M.I. et al. (2017) Regulation of structure and phase composition of titanium aluminides produced by zone melting. Dopovidi NANU, 6, 36-44 [in Russian].

12. Kartavykh, A.V., Tcherdyntsev, V.V., Gorshenkov, M.V. et al. (2013) Tailored microstructure creation of TiAl-based refractory alloys within VGF solidification. Materials Chemistry and Physics, 141(2-3), 643-650. https://doi.org/10.1016/j.matchemphys.2013.05.037

13. Ganina, S.M., Ginkin, V.P., Chernov, K.G. (2014) Mathematical model of heat and mass transfer during crucibleless melting of TiAl intermetallides. VANT. Seriya Matematicheskoe Modelirovanie Fizicheskikh Protsessov, 4, 35-43 [in Russian].

14. Kartavykh, A.V., Asnis, E.A., Piskun, N.V. et al. (2017) Room-temperature tensile properties of float-zone processed β-stabilized γ-TiAl (Nb, Cr, Zr) intermetallic. J. Materials Letters, 188, 88-91. https://doi.org/10.1016/j.matlet.2016.10.103

15. Lobanov, L.M., Asnis, E.A., Piskun, N.V., Statkevich, I.I. (2018) Improvement of structure and mechanical characteristics of structural intermetallics of titanium-aluminium system at directed crystallization. Dopovidi NANU, 12, 51-60 [in Russian]. https://doi.org/10.15407/dopovidi2018.12.051

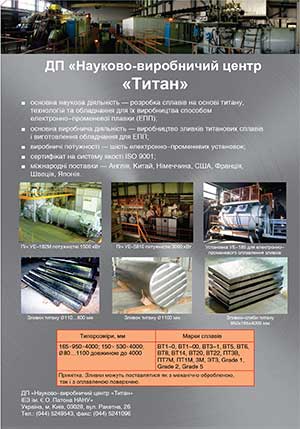

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.