| 2021 №04 (01) |

DOI of Article 10.37434/sem2021.04.02 |

2021 №04 (03) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2021, #4, 16-19 pages

Formation of a layer of high-chromium cast iron in current-conducting mould of a square cross-section at electroslag surfacing

A.V. Netyaga, Yu.M. Kuskov, V.M. Proskudin, V.A. Zhdanov, I.P. Lantyugov

E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., Kyiv, 03150, Ukraine. E-mail: office@paton.kiev.ua

Abstract

Technological assessment of operation of current-conducting mould of a round cross-section at electroslag surfacing (remelting) was performed. Mould design with forming portion of 200×200 mm square cross-section was proposed. Test melts were conducted in the new mould using consumable electrodes from high-chromium cast iron of 120×120 mm square cross-section. High-quality bimetal blanks from St 3 steel + high-chromium cast iron were produced with layer ratio of 12 and 25, respectively. It is planned to use the blanks as reinforcing elements to protect rapidly-wearing mining equipment parts. Ref. 12, Tabl. 1, Fig. 4.

Keywords: electroslag surfacing; remelting; current-conducting mould; square cross-section; high-chromium cast iron

Received 20.12.2021

References

1. Ksyondzyk, G.V. (1975) Сurrent-conducting mould providing the rotation of slag pool. Spest. Elektrometallurgiya, 27, 32–40 [in Russian].2. Kuskov, Yu.M. (2001) Electroslag technologies for producing and restoration of forming rolls. Stal, 8, 70–75 [in Russian].

3. Kuskov, Yu.M. (2003) A new approach to electroslag welding. Welding J., 4, 42–45.

4. Shabanov, V.B., Sviridov, O.V., Belobrov, Yu.N. et al. (1999) Creation of complex ESS by liquid filler metal of working rolls for continuous wide-strip hot rolling mills. Avtomatich. Svarka, 9, 51–54 [in Russian].

5. Sarychev, I.S., Skorokhodov, V.N., Chernov, P.P. et al. (2001) Restoration of cast iron working rolls by electroslag surfacing. Proizvodstvo Prokata, 1, 28–30 [in Russian].

6. Kuskov, Yu.M., Kuprin, I.N., Sarychev, I.S. (2006) Thermal processes in electroslag surfacing forming rolls in current- conducting mould. Svarochn. Proizvodstvo, 10, 29–32 [in Russian].

7. Shevchenko, V.E. (2001) Electroslag technology in production of modern forming rolls: Syn. of Thesis for Cand. of Tech. Sci. Degree. Kiev, PWI [in Russian].

8. Kuskov, Yu.M. (1996) Experience of electroslag surfacing of flat blanks in current-conducting mould. Avtomatich. Svarka, 7, 54–55 [in Russian].

9. Kuskov, Yu.M., Tsykulenko, K.A. (2009) Development of design of current-conducting mould for electroslag surfacing of flat blanks. Stal, 1, 41-46 [in Russian]. https://doi.org/10.3103/S0967091209010136

10. Tsykulenko, K.A., Vislobokov, O.M. (2008) Physical modeling of slag pool hydrodynamics in slab current-leading mould. Pt 2. Cladding. Advances in Electrometallurgy, 3, 17-20.

11. Kuskov, Yu.M., Soloviov, V.G., Zhdanov, V.A. (2017) Electroslag surfacing of end faces with large-section electrode in current-supplying mould. The Paton Welding J., 11, 29-32. https://doi.org/10.15407/tpwj2017.12.05

12. Kuskov, Yu.M. (2018) Influence of flux composition on the process of electroslag surfacing of end faces with discrete feeding of filler material. Ibid., 1, 33-37. https://doi.org/10.15407/tpwj2018.01.07

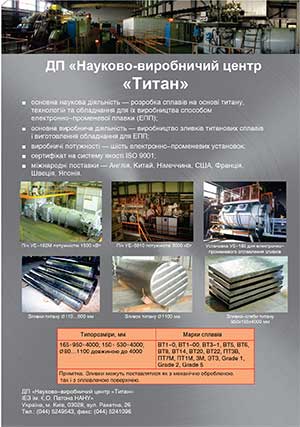

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.