| 2022 №01 (01) |

DOI of Article 10.37434/sem2022.01.02 |

2022 №01 (03) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2022, #1, 16-23 pages

Influence of microstructure of multilayer Al/Ni foils on phase transformations initiated by heating

A.I. Ustinov, S.O. Demchenkov

E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., Kyiv, 03150, Ukraine. E-mail: office@paton.kiev.ua

Abstract

At heating of multilayer Al/Ni foil the component interdiffusion is accompanied by phase transformations, which can be occur by a two-channel multistage or single-channel single-stage schemes. It is shown that the type of the scheme by which the phase transformations develop in the studied multilayer foils, is related to the process of formation of a metastable Al9Ni2-phase on the layer interfaces. The work is a study of the influence of multilayer foil microstructure on formation of a metastable Al9Ni2-phase. It is found that the thickness of Al9Ni2-phase layers is determined by the thickness of aluminium layers in the initial multilayer foil. At the thickness of Al layers of 70…80 nm and greater, the thickness of Al9Ni2-phase layers practically does not change, and is equal to approximately 30..35 nm; at reduction of Al layer thickness, the thickness of Al9Ni2-phase layers decreases abruptly, and at Al thickness less than 10…12 nm, the layers of metastable Al9Ni2-phase do not form. The process of formation of metastable Al9Ni2-phase layers is characterized by a high rate and incubation time. Proceeding from the obtained results, a structural-kinetic diagram was proposed, which allows determination of the conditions for prevention of the multistage process of achievement of the foil equilibrium state during its heating. Ref. 15, Table 1, Fig. 8.

Keywords: multilayer foils; electron beam deposition; phase transformations; intermetallics; SHS reaction

Received 24.11.2021

References

1. Ramos, A.S., Vieira, M.T., Simões, S. et al. (2010) Reaction-assisted diffusion bonding of advanced materials. Defect and Diffusion Forum, 297-301, 972-977. https://doi.org/10.4028/www.scientific.net/DDF.297-301.9722. Duckham, A., Spey, S.J., Wang, J. et al. (2004) Reactive nanostructured foil used as a heat source for joining titanium. J. of Applied Physics, 96, 2336-2342. https://doi.org/10.1063/1.1769097

3. Zaporozhets, T.V., Gusak, A.M., Ustinov, A.I. (2010) SHS reactions in nanosized multilayers: Analytical model versus numerical one. Intern. J. of Self-Propagating High-Temperature Synthesis, 19(4), 227-236. https://doi.org/10.3103/S1061386210040011

4. Grapes, M.D., LaGrange, T., Woll, K. et al. (2014) In situ transmission electron microscopy investigation of the interfacial reaction between Ni and Al during rapid heating in a nanocalorimeter. APL Materials, 2, 116102-1-116102-7. https://doi.org/10.1063/1.4900818

5. Ustinov, A., Demchenkov, S. (2017) Influence of metastable Al9Ni2 phase on the sequence of phase transformations initiated by heating of Al/Ni multilayer foils produced by EBPVD method. Intermetallics, 84, 82-91. https://doi.org/10.1016/j.intermet.2017.01.005

6. Sauvage, X., Dindab, G.P., Wildeb, G. (2007) Non-equilibrium intermixing and phase transformation in severely deformed Al/Ni multilayers. Scripta Materialia, 56, 181-184. https://doi.org/10.1016/j.scriptamat.2006.10.021

7. Blobaum, K.J., Van Heerden, D., Gavens, A.J., Weihs, T.P. (2003) Al/Ni formation reactions: Characterization of the metastable Al9Ni2 phase and analysis of its formation. Acta Materialia, 51, 3871-3884. https://doi.org/10.1016/S1359-6454(03)00211-8

8. Trenkle, J.C., Koerner, L.J., Tate, M.W. et al. (2010) Time-resolved X-ray microdiffraction studies of phase transformations during rapidly propagating reactions in Al/Ni and Zr/Ni multilayer foils. J. of Applied Physics, 107, 113511. https://doi.org/10.1063/1.3428471

9. Ishchenko, A.Ya., Falchenko, Yu.V., Ustinov, A.I. et al. (2007) Diffusion welding of finely-dispersed AMg5/27%Al2O3 composite with application of nanolayered Ni/Al foil. The Paton Welding J., 5(7), 2-5.

10. Da Silva Bassani, M.H., Perepezko, J.H., Edelstein, A.S., Everett, R.K. (1997) Initial phase evolution during interdiffusion reactions. Scripta Materialia, 37(2), 227-232. https://doi.org/10.1016/S1359-6462(97)00078-X

11. Pasichnyy, M.O., Schmitz, G., Gusak, A.M., Vovk, V. (2005) Application of the critical concentration gradient to the nucleation of the first product phase in Co/Al thin films. Physical Review B, 72(1), 014118-1-014118-7. https://doi.org/10.1103/PhysRevB.72.014118

12. Zhou, X.W., Johnson, R.A., Wadley, H.N.G. (1997) Vacancy formation during vapor deposition. Acta Materialia, 45(11), 4441-4452. https://doi.org/10.1016/S1359-6454(97)00156-0

13. Gusak, A.M., Zaporozhets, T.V., Lyashenko, Yu.O. et al. (2010) Diffusion-controlled solid state reactions: Alloys, Thin-films and Nanosystems, Wiley-VCH, Berlin. https://doi.org/10.1002/9783527631025

14. Petrantoni, M., Hémeryck, A., Ducéré, J. et al. (2010) Asymmetric diffusion as a key mechanism in Ni/Al energetic multilayer processing: A first principles study. J. of Vacuum Sci. and Technology, 28(6), 15-17. https://doi.org/10.1116/1.3491182

15. Yücelen, E. (2011) Characterization of Low-dimensional structures by Advanced Transmission Electron Microscopy. PhD thesis, Delft University of Technology.

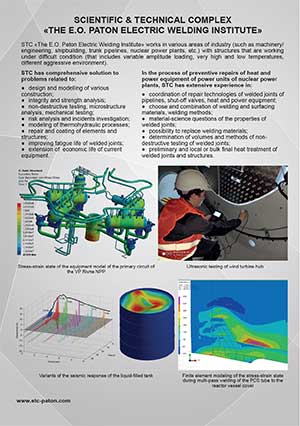

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.