| SCIENTIFIC AND TECHNICAL | |||||||||||||||||||||||||||||||||||||||||||||

| Makhnenko V.I., Milenin A.S. and Semyonov A.P. Mathematical modelling of thermal-deformation processes in braze-welding of butt joints of the titanium-aluminium type | 2 | ||||||||||||||||||||||||||||||||||||||||||||

Mathematical model of thermal-deformation processes occurring in braze-welding of butt joints between titanium and aluminium was developed. Analysis of these processes was conducted within the frames of this model, and recommendations were worked out for optimisation of production of passenger aircraft seat tracks comprising dissimilar joints.

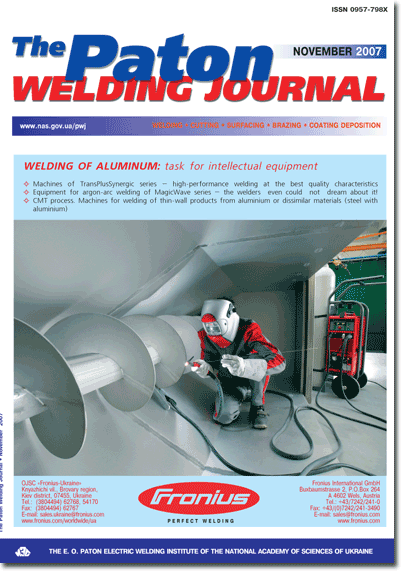

| Ishchenko A.Ya. Welding of aluminium alloys (directions of research conducted at PWI) | 6 |

The main directions of investigations conducted at the E.O. Paton Electric Welding Institute over half a century in the field of arc welding of aluminium alloys are outlined. Examples of an effective application of technologies of arc welding of aluminium alloys in construction of various structures are given.

| Ternovoj E.G., Shulym V.F., Khaskin V.Yu., Shelyagin V.D., Lozovskaya A.V. , Siora A.V. and Bernatsky A.V. Properties and structure of hybrid laser-plasma welded joints in aluminium alloys | 10 |

The process of production of joints in aluminium alloys by the hybrid laser-plasma method was investigated. Peculiarities of properties and structure of these joints were studied. Welding experiments were conducted both with and without filler wire, which allowed porosity of the welded joints to be eliminated and their properties to be considerably improved.

| Labur T.M., Ishchenko A.Ya., Taranova T.G., Kostin V.A. and Grigorenko G.M. Investigation of the fracture mode of welded joints of high-strength alloy V96tss under the conditions of off-center tension | 16 |

Regularities of initiation and propagation of cracks in V96tss alloy under the conditions of off-center tension have been studied. Fractographic analysis was used to establish the causes and mechanisms of initiation of fracture sites in individual sections of welded joint HAZ after different conditions of welding heating.

| Zhadkevich M.L., Tretyak N.G., Kavunenko P.M., Zelenin V.I., Mokhort V.A. and Zelenin E.V. Friction stir welding and surfacing of copper and its alloys | 22 |

Peculiarities of structure of welded and surfaced joints of the L60 brass and the M1 copper produced by friction stir welding were investigated. High quality of welds, absence of defects and inhomogeneities in the welding zone was noted. Technology for friction stir surfacing of copper by production of overlapped slot welds was developed.

| INDUSTRIAL | Ishchenko A.Ya., Podielnikov S.V. and Poklyatsky A.G. Friction stir welding of aluminium alloys (Review) | 25 |

The state-of-the-art of friction stir welding, working tool designs, joint types when this welding process is used, features of formation of joints of different aluminium alloys and their properties are considered. The main applications of friction stir welding are described.

| Knysh V.V. and Kovalchuk V.S. Extension of service life of metal structures from low-alloy steels by high-frequency mechanical peening after repair welding | 31 |

To extend the life time of metal structures in repair welding using the standard technology, it is recommended to treat the fusion zone between the repair weld and base metal by high-frequency mechanical peening (HFMP). HFMP strengthening of the welded joints on steel 09G2S in as-welded condition and after repair welding provides a 3Д5 times increase of their cyclic life in single-frequency zero-to-tension axial stress cycle.

| Rudenko P.M. and Gavrish V.S. KSU KS 02 system for automatic control and monitoring of resistance spot welding process | 34 |

Methods for real-time quality control of resistance spot welding are considered. Universal system for control and monitoring, peculiar features of which are wide possibilities for real-time quality control, is suggested. Technical characteristics of the system are presented, and fields of its application in industry are shown.

| Zalevsky A.V., Galinich V.I., Osipov N.Ya., Netyaga V.I. and Kirichenko O.P. Welding-technological properties of new AN-47DP grade flux | 36 |

Results of tests of a new fused flux, designed for welding of high-strength low-alloy steels, are presented. The flux, produced according to the double-refining method and designated as the AN-47DP grade flux, was developed within the framework of innovation project of the «E.O. Paton Electric Welding Institute Technological Park».

| BRIEF INFORMATION | Developments in the field of aluminium alloys offered by the E.O.Paton Electric Welding Institute | 42 | Theses for scientific degree | 51 | News | 53 | Developed at PWI | 9 | | |||||||||||

(You are viewing the simplified file contents)

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.