| 2021 №10 (05) |

DOI of Article 10.37434/tpwj2021.10.06 |

2021 №10 (07) |

The Paton Welding Journal, 2021, #10, 38-46 pages

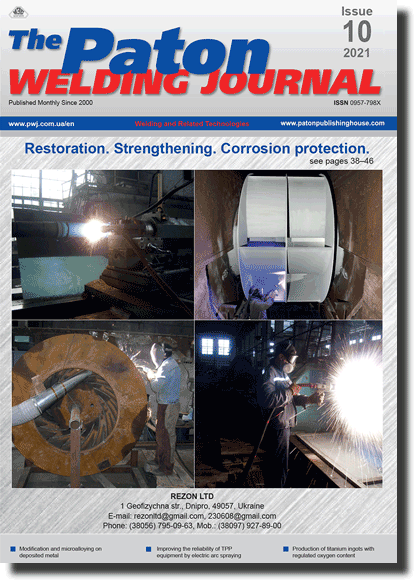

Improving the reliability of power complex equipment by electric arc spraying

A.V. Hruzevych1 and V.V. Shvets2

1Trypillia TPP PJSC «Centrenergo» 1 Promyslova Str., 08720, Ukrainka, Ukraine Institute of Magnetism of the NASU and Ministry of Education and Science of Ukraine 36-b Akademik Vernadsky Blvd, 03142, Kyiv, Ukraine

2Chief Technologist Department «REZON», LLC 1 Geofizychna Str., 49057, Dnipro, Ukraine

Abstract

The aim of the work is studying the efficiency of spraying application to improve the reliability of TPPs power equipment. A feasibility study indicated that the introduction of spraying technology can reduce losses in case of TPPs emergency shutdowns by 1.5–3.0 times a year, and the estimated extension of the service life of surfaces increases by 1.7–2.5 times. Since the main type of wear in the feed-water economizer (FWE) of TPP boilers is ash wear, and corrosion between the spacing bars, a comprehensive solution was proposed for the problem of extending the service life of boiler waterwall tubes and economiser tubes through development of new heat-resistant and wear-resistant thermal coatings.

Keywords: spraying, welding, thermal power plant, ash wear, corrosion, electric arc coating

Received: 20.08.2021

Accepted: 11.11.2021

References

1. Shrajber, A.A., Yatsenko, V.P. (2008) Modeling of arbrasive wear of convective heat exchange surface of boiler. Problemy Zagalnoi Energetyky, 17, 37-40 [in Russian].2. Accident rate in the facilities of electrical power engineering of Ukraine in 2004. http://mpe.kmu.gov.ua/minugol/control/uk/doccatalog/list.

3. Inspection of technology violoation in electrical power engineering of Ukraine in fourth quarter of 2005. http://mpe. kmu.gov.ua/minugol/control/uk/doccatalog/list

4. Soltani, M., Chahartaghi, M., Majid Hashemian, S., Faghih Shojaei, A. (2020) Technical and economic evaluations of combined cooling, heating and power (CCHP) system with gas engine in commercial cold storages. Energy Conversion and Management, 214. Article number: 112877. https://doi.org/10.1016/j.enconman.2020.112877

5. Yang, S., Zhang, L., Fan, J., Sun, B. (2021) Experimental study on erosion behavior of fracturing pipeline involving tensile stress and erosion prediction using random forest regression. J. of Natural Gas Sci. and Engin., 87. Article number: 103760. https://doi.org/10.1016/j.jngse.2020.103760

6. Maidanik, M.N., Tugov, A.N., Vereshchetin, V.A. (2020) Assessment of Boiler Units` Technical State Based on Quality Indicators. Thermal Engineering, 67(4), 216-222. https://doi.org/10.1134/S0040601520040047

7. Kiselev, S.P., Kiselev, V.P., Maximovsky, E.A. et al. (2019) Mechanism of formation of intermetallic coatings by the cold spray technology. J. of Physics, Conf. Series, 1677, 1. Article number: 012136. https://doi.org/10.1088/1742-6596/1677/1/012136

8. Sethi, A.K. (2020) Studies on hard surfacing of structural steel by gas thermal spraying process. In: Proc. of Int. Conf. on Mechanical and Energy Technologies, 21, 1436-1440. https://doi.org/10.1016/j.matpr.2019.09.173

9. Shatov, A.P. (2009) Welding and repair of metal structures of anticorrosion coatings. Moscow, MGTU [in Russian].

10. Panteleenko, F.I., Snarsky, A.S., Krylenko, A.V. (2012) Peculiarities of structure degradation and mechanical properties of components of furnace and heat-and-power engineering equipment after long term service. Nauka i Tekhnika, 1, 16-20 [in Russian].

11. Som Dutt Sharma, S.D., Saluja, R., Moeed, K.M. (2013) A review on the effect of preheating and/or post weld heat treatment (PWHT) on hardened steel. Int. J. of Technical Research and Applications, 1, 5-7.

12. Feng, L., Yang, N. (2019) Stainless Steel Welding and Development Trend of Welding Technology. IOP Conference Series: Earth and Environmental Science, 252, 2, Article number: 022117. https://doi.org/10.1088/1755-1315/252/2/022117

13. Yatsenko, V.P. (2006) Prediction of erosion wear of heat exchange surfaces ob boiler equipment. Problemy Zagalnoi Energetyky, 13, 81-85 [in Russian].

14. Birkin, P.R., Lear, R., Webster, L. et al. (2020) In-situ detection of single particle impact, erosion/corrosion and surface roughening. Wear, 464-465. Article number: 203527. https://doi.org/10.1016/j.wear.2020.203527

15. Korzh, V.M. (2005) Thermal treatmentaterials. Kyiv, Ekotekhnologiya [in Ukrainian].

16. Lashchenko, G.I. (2012) Modern technologies of welding production. Kiev, Ekotekhnologiya [in Russian].

17. Hirohata, M., Takeda, F., Konishi, H., Itoh, Y. (2018) Effect of weld line direction and paint orientation on corrosion and paint deterioration characteristics of welded part of steel. Corrosion Engin. Sci. and Technology, 53(8), 591-600. https://doi.org/10.1080/1478422X.2018.1514133

18. Instruction on restoration of worn-out and new bends and straight pipe areas of heating surfaces of high-pressure boilers by gas powder surfacing. I 34-70-027-87 [in Russian]. http://online.budstandart.com/ru/catalog/doc-page?id_doc=68749.

19. Grechneva, M.V., Goppe, G.G. (2015) Gas powder spraying of heating surface pipes of boiler units of thermal power stations. Vestnik IrGTU, 11, 106, 23-27 [in Russian].

20. Malchevsky, I.A., Bespalov, S.A. (2017) Prospective scientific and technical developments. Energetyka ta Energoefektyvnist. Kyiv, Akademperiodyka [in Ukrainian].

21. TU U 14-3-460:2009/ТU U 27.2-05757883-207:2009: Seamless steel pipes for steam boilers and pipelines [in Russian]. https://files.stroyinf.ru/Index2/1/4293733/4293733499.htm

22. ТІ 00130044.25101.00549: Deposition of protective coating on coils of feed-water economizer and water wall tubes of boiler TP-100. Lviv, SE Lviv Design Bureau. https://patonpublishinghouse. com/eng/journals/as/2019/05/04/

23. RD.15.027-89: Welding, heat treatment and inspection of pipe systems of boilers and pipelines in mounting and repair of power plant equipment. http://docs.cntd.ru/document/1200026674

24. Ruff, A.W., Wiederhorn, S.M. (1979) Erosion by solid particle impact. Treatise on Mater. Sci. and Technol., 16, 69-126. https://doi.org/10.6028/NBS.IR.78-1575

Suggested Citation

A.V. Hruzevych and V.V. Shvets (2021) Improving the reliability of power complex equipment by electric arc spraying. The Paton Welding J., 10, 38-46.The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.