| 2015 №09 (07) |

DOI of Article 10.15407/tpwj2015.09.08 |

2015 №09 (09) |

The Paton Welding Journal, 2015, #9, 50-52 pages

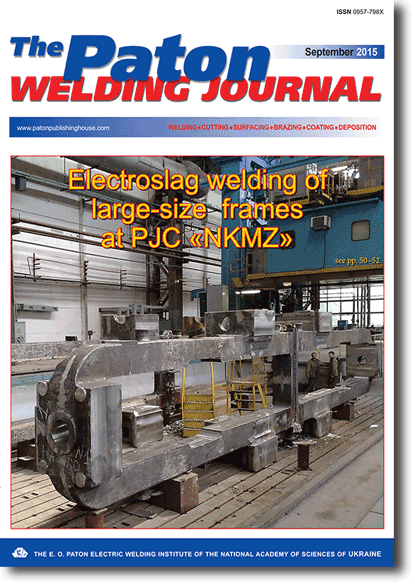

Manufacturing large-sized beds by consumable-nozzle electroslag welding

K.P. Shapovalov1, V.A. Belinsky1, S.N. Kosinov1, S.N. Litvinenko1, K.A. Yushchenko2, I.I. Lychko2 And S.M. Kozulin2

1Company «NKMZ». 4 Ordzhonikidzhe Str., Kramatorsk, Donetsk reg., Ukraine

2E.O. Paton Electric Welding Institute, NASU. 11 Bozhenko Str., 03680, Kiev, Ukraine. E-mail: office@paton.kiev.ua

Abstract

PWI in collaboration with Novo-Kramatorsk Machine-Building Works (NKMZ company) continues improving electroslag welding technology. This work provides a description of the technology of consumable-nozzle electroslag welding in manufacture of large-sized beds with butts of 420-460 Ф 2200-2380 and 940-1120 Ф 1040-1250 mm cross-section. Machine time shortening almost 2 times was achieved. Welded joints of large-sized cast-welded billets of beds for high-capacity mills are characterized by high quality. 8 Ref., 5 Figures.

Keywords: electroslag welding, consumable nozzle, large-sized beds, heating, intermediate tempering, machine time reduction

Received: 28.05.15

Published: 26.10.15

References

- (1980) Electroslag welding and cladding. Ed. by B.E. Paton. Moscow: Mashinostroenie.

- Sterenbogen, Yu.A., Pogorelov, V.S. (1956) Electroslag welding of body of scale breaker. Avtomatich. Svarka, 4, 108-114.

- Paton, B.E., Dudko, D.A., Yushchenko, K.A. et al. (1987) Electroslag welding: Results, problems and prospects of development. Ibid., 5, 32-42.

- Sushchuk-Slyusarenko, I.I., Lychko, I.I., Koval, I.M. et al. (1968) Producing exact sizes of large-dimensioned bodies in electroslag welding. Ibid., 11, 55-58.

- Nevidomsky, V.A., Krasilnikov, S.G., Panin, A.D. et al. (2002) New machine for electroslag welding of large parts at JSC «NKMBF». The Paton Welding J., 2, 49-51.

- Litvinenko, S.N., Shapovalov, K.P., Savchenko, I.S. et al. (2013) Systems of process control and monitoring of conditions - the important factors of quality assurance in electroslag welding of thick metal. Ibid., 12, 39-41.

- Yushchenko, K.A., Lychko, I.I., Sushchuk-Slyusarenko, I.I. (1999) Effective techniques of electroslag welding and prospects for their application in welding production. In: Welding and Surfacing Rev., Vol. 12, 1-108.

- Karzov, G.P., Galyatkin, S.N., Varovin, A.Ya. et al. (2009) Automatic submerged-arc welding of elements of superthick structures. Voprosy Materialovedeniya, 3, 357-371.

Suggested Citation

K.P. Shapovalov, V.A. Belinsky, S.N. Kosinov, S.N. Litvinenko, K.A. Yushchenko, I.I. Lychko And S.M. Kozulin (2015) Manufacturing large-sized beds by consumable-nozzle electroslag welding. The Paton Welding J., 09, 50-52.The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.