| 2022 №05 (05) |

DOI of Article 10.37434/tpwj2022.05.06 |

2022 №05 (07) |

The Paton Welding Journal, 2022, #5, 40-45 pages

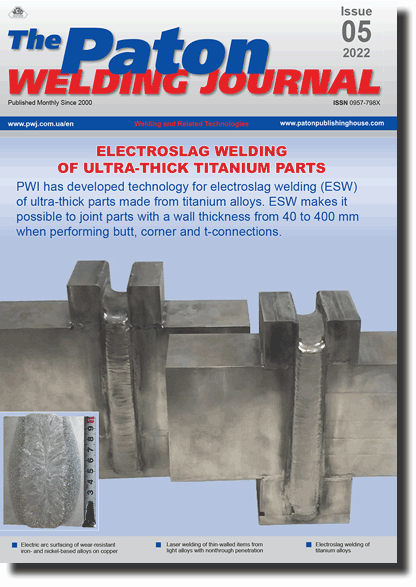

Structure and properties of electroslag welded joints of VT6 titanium alloy

I.V. Protokovilov, V.O. Shapovalov, V.B. Porokhonko, S.G. Hrygorenko

E.O. Paton Electric Welding Institute of the NASU. 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: lab38@paton.kiev.ua

Abstract

The paper presents the results of investigations of the quality of electroslag welded joints of 100 mm plates from VT6 titanium alloy. Investigations included X-ray inspection, chemical and gas analysis, optical metallography, mechanical tensile and impact toughness tests, as well as fractographic analysis. X-ray inspection and optical metallography of the welded joint showed absence of surface and inner defects in the weld metal and HAZ. Gas analysis of the weld metal demonstrated its correspondence to standard requirements to VT6 alloy. Ultimate strength of weld metal was equal on average to 90 % of base metal strength, and impact toughness (KCU) was 1.6 times higher than in the base metal. Fractures of metal of the weld and HAZ were of transcrystalline mode of a mixed type, with areas of both ductile and brittle fracture. It is shown that the welded joint mechanical properties are determined, primarily, by the size of grains and microstructure of the weld metal and HAZ, forming under the conditions of a low cooling rate and a high heat input, characteristic for electroslag welding process.

Keywords: VT6 titanium alloy; electroslag welding; welded joint; structure; mechanical properties; fracture mode

Received: 21.04.2022

Accepted: 08.08.2022

References

1. Paton, B., Yushchenko, K., Kozulin, S., Lychko, I. (2019) Electroslag welding process. Analysis of the state and tendencies of development (Review). The Paton Welding J., 10, 33-40. https://doi.org/10.15407/tpwj2019.10.052. Yushchenko, K., Lychko, I., Kozulin, S. et al. (2018) Application of welding in construction. The Paton Welding J., 9, 23-27. https://doi.org/10.15407/tpwj2018.09.05

3. Kaluc, E., Taban, E., Dhoogev, A. (2006) Electroslag welding process and industrial applications. Metal Dunyasi, 152(13), 100-104.

4. Yushchenko, K., Kozulin, S., Lychko, M., Kozulin, M. (2014) Joining of thick metal by multipass electroslag welding. Ibid., 9, 30-33. https://doi.org/10.15407/tpwj2014.09.04

5. Paton, B., Dudko, D., Palti, A. et al. (1999) Electroslag welding (Prospects of development). Avtomatich. Svarka, 9, 4-6 [in Russian].

6. Shcherbinin, E., Kompan, Ya. (2005) MHD Technologies of Electroslag welding and melting of Titanium alloys for aerospace industry. Proc. of 15th Riga and 6th Pamir Conf. on Fundamental and Applied MHD, 287-290.

7. Devletian, J., Chen, S.J., Wood, W. et al. (1990) Fundamental aspects of electroslag welding of titanium alloys. Recent trends in welding science and Technology. ASM Intern., 419-424.

8. Chen, S.J., Devletian, J.B. (1990) Microstructure and mechanical properties of electroslag welds in Ti-6A1-4V alloy. Weld. J., 69(9), 319-324.

9. Protokovilov, I., Porokhonko, V., Petrov, D. (2013) Technological peculiarities of electroslag narrow-gap welding of titanium. The Paton Welding J., 1, 34-38.

Suggested Citation

I.V. Protokovilov, V.O. Shapovalov, V.B. Porokhonko, S.G. Hrygorenko (2022) Structure and properties of electroslag welded joints of VT6 titanium alloy. The Paton Welding J., 05, 40-45.The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.