| 2020 №01 (04) |

DOI of Article 10.37434/sem2020.01.05 |

2020 №01 (06) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2020, #1, 39-45 pages

Research of the influence of thermoanthracite calcination modes for the production of continuous self-baking electrodes for ore reducing furnaces

S.V. Kutuzov1, V.V. Derkach1, M.I. Gasik2, A.P. Gorobets2, M.M. Gasik3

1Private Joint Stock Company Ukrainian Graphite. 20 Northern Highway, 69600, Zaporozhye, Ukraine. Е-mail: tehnology@ukrgrafit.com.ua

2National Metallurgical Academy of Ukraine. 4 Gagarina Ave., 49000, Dnipro, Ukraine. E-mail: tehnosplavy@ua.fm

3Aalto University. Finland, Espoo, PO BOX 11000 FI-00076. E-mail: michael.gasik@aalto.fi

Abstract

The process of graphitization of anthracite as a carbon component of self-baking electrodes is considered. Experimental studies of the physical properties of thermoanthracite by thermogravimetry and IR spectroscopy in the temperature range 400…1400 °C were performed. Regression models of the relationship between the structure of thermoanthracite, strength, thermal conductivity and resistivity and the temperature regime of anthracite calcination were created. Ref. 9, Tabl. 4, Fig. 7.

Keywords: thermoanthracite; self-baking electrodes; thermophysical characteristics; dynamic thermogravimetry; IR spectroscopy; crystallites; density; electrical conductivity; phase composition

Received 11.02.2020

References

1. Gasik, M.I. (1984) Electrodes of ore reduction furnaces. Moscow, Metallurgiya [in Russian].2. Stach, E., Mackowsky, M.-Th., Teichmüller, M. et al. (1978) Coal petrology. Ed. I.V. Eremin, N.P. Grechishnikov. Moscow, Mir [in Russian].

3. Drozdnik, I.D., Kaftan, Yu.S., Dolzhanskaya, Yu.B. et al. (2002) Anthracite: Reserves. Production. Properties. Application. Koks i Khimiya, 12, 2–8 [in Russian].

4. Gasik, M.M., Gasik, M.I., Urazlina, O.Yu., Kutuzov, S.V. (2006) Precision thermokinetic studies of transformations in Donetsk anthracite when it is calcined in air and argon in the range of 100–1400 °С. Metallurgicheskaya i Gornorudnaya Promyshlennost, 1, 26–30 [in Russian].

5. Gasik, M.M., Gasik, M.I., Petrov, B.F. et al. (2006) Computer modeling and pilot development of the technology of onestage calcination of anthracite in an electrocalciner. Ibid., 3, 27–30 [in Russian].

6. Brandtzag, S.R., Linda, H., Oye, H.A. (1983) Structural changes in graphite by heat treatment. Light Metals. In: Proc. Techn. Ses. 112 AIME Annu. Meet. (March 6–10, 1983, Atlanta), 711–725.

7. Pusz, S., Kwiecinska, B.K., Duber, S. (2003) Textural transformation of thermally treated anthracites. Int. J. Coal Geol. 1-2, 115-123. https://doi.org/10.1016/S0166-5162(03)00024-7

8. Lakomsky, V.I., Kutuzov, S.V. (2006) On temperature dependence of thermoanthracite electrical resistance. Advances in Electrometallurgy, 1, 35–37.

9. Gasik, M.M., Gasik, M.I., Urazlina, O.Yu. (2004) Modeling of the thermal and electric modes of operation of the electrocalcinator during the thermal treatment of thermoanthracite. Metallurgicheskaya i Gornorudnaya Promyshlennost, 5, 18–23 [in Russian].

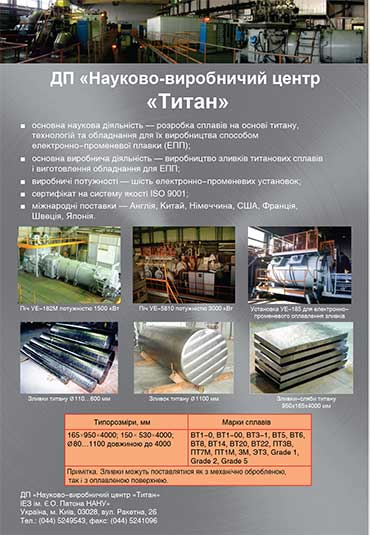

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.