| 2020 №01 (03) |

DOI of Article 10.37434/sem2020.01.04 |

2020 №01 (05) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2020, #1, 32-38 pages

Corrosion and erosion resistance of copper and molybdenum composite materials condensed from the vapour phase

I.M. Grechanyuk1, V.G. Grechanyuk2

1SPC «ELTECHMASH». 25 Vatutina Str., 21011, Vynnitsa, Ukraine. E-Mail: vin25ebt@ukr.net

2Kyiv National University of Construction and Architecture. 31 Povitroflosky Ave., 03037, Kyiv, Ukraine. E-Mail: knuba@knuba.edu.ua

Abstract

The corrosion and erosion resistance of copper and molybdenum-based composite materials used as contact materials are considered in the paper. It is found that zirconium and yttrium (material MDK-3: Cu–(10…12 %) Mo–(0.2 %) Zr, Y) when introduced into the Cu–Mo system, increase the corrosion resistance by 20 % and the deep corrosion index decreases to 0.02 g/(m2·year). It is shown that the dependence of contact temperature change on the contact resistance is linear, the higher the contact resistance, the more intensively the contact temperature increases. The dependence of contact resistance of contacts made of materials MDK-3 and Ag–CdO on the number of switching cycles is established. The characteristics of contacts made of silver-containing materials and contact materials from MDK-3 were compared, and the advantages of the latter were shown. Ref. 9, Tabl. 1, Fig. 8.

Keywords: composite materials; corrosion resistance; contact resistance; contact materials, dispersion-strengthened materials

Received 14.12.2019

References

1. Grechanyuk, V.G. (2013) Physical-chemical principles of formation of copper-based composite materials condensed from vapor phase: Syn. of Thesis for Dr. Chem. Sci. Degree. Kyiv, 40 [in Ukrainian].2. Grechanyuk, N.I., Minakova, R.V., Vasilega, O.P. et al. (2010) State-of-the art and prospects of application of high-velocity electron beam evaporation technology and subsequent vacuum condensation of metals and nonmetals for producing of electric contact and electrodes. In: Collect. of IPS NASU: Electric contacts and electrodes. Kiev, 54−57 [in Russian].

3. Grechanyuk, N.I., Grechanyuk, V.G. (2018) Dispersed and laminar volumetric nanocrystal materials on base of copper and molybdenum. Structure, properties, technology, application. Information 1. Structure and phase composition. Sovrem. Elektrometall., 1, 42−53 [in Russian]. https://doi.org/10.15407/sem2018.01.06

4. Grechanyuk, N.I., Grechanyuk, V.G. (2019) Mechanical properties of dispersed and laminar composite materials on copper and molybdenum base. Ibid., 2, 43−49 [in Russian]. https://doi.org/10.15407/sem2019.02.07

5. (1980) Unified procedures of laboratory testing of effectiveness of corrosion inhibitors in aqueous systems. Riga, Inst. of Inorganic Chemistry [in Russian].

6. Grechanyuk, I.N., Grechanyuk, V.G., Emelyanov, B.M., Rudenko, I.F. (1998) Corrosion of composite materials on copper base applied for electric contacts. In: Collect. of IPS NASU: Electric contacts and electrodes. Kiev, 140−144 [in Russian].

7. TU U 20113410.001−98: Dispersion-strengthened materials for electric contacts [in Russian].

8. TU U 24.4-53966101.2014: Dispersion-strengthened materials for electric contacts [in Ukrainian].

9. TU U 31.2-20113410-003−2002: Electric contacts based on dispersion-strengthened materials (MDK) [in Russian].

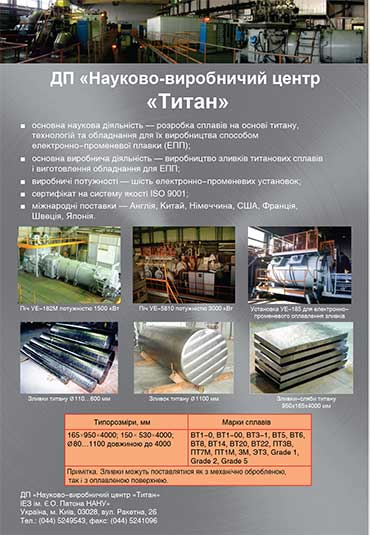

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.