| 2020 №03 (08) |

DOI of Article 10.37434/sem2020.03.01 |

2020 №03 (02) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2020, #3, 11-17 pages

Investigation of manufacturability and effectiveness of the new slag for electrosdlag remelting

G.P. Stovpchenko2, S.V. Davidchenko3, L.O. Lisova1, Ya.V. Gusev1, L.B. Medovar1

1E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: office@paton.kiev.ua

2Engineering Company «ELMET-ROLL». P.o. 259, 03150, Kyiv. E-mail: office@elmet-roll.com.ua

3PJSC A.M.Kuzmin «Electrometallurgical Plant «Dniprospetsstal». 81 Pivdenne Highway, 69008, Zaporizhzhya. E-mail: info@dss.com.ua

Abstract

Pilot trials testified that by the main characteristics of chemical composition, micro- and macrostructure, and mechanical properties of the manufactured bars, the metal of ingots from 15Х11МФ (15Cr11MoV) steel, melted under the developed slag ANF-39 (32CaF2/31Al2O3/30CaO/4MgO/3SiO2), is highly competitive with the products, remelted using slag ANF-6 (70CaF2/30Al2O3), which is applied in batch production by the current technology. Compared to slag ANF-39, application of slag ANF-6 allowed reducing oxide inclusion content by 0.5 points and power consumption at electroslag remelting by 17 %; the slag is more eco-friendly due to lowering calcium fluoride content more than 2 times; the cost of materials for slag production was reduced by 23…25 %. Slag ANF-39 is recommended for replacement of ANF-6 for ESR of alloyed and high-alloyed steels in stationary and short-collar molds. Ref. 8, Tabl. 5, Fig. 4.

Keywords: new slag; electroslag remelting; energy effectiveness; high-alloyed steel; macro- ad microstructure; nonmetallic inclusions

Received 03.08.2020

References

1. Prjsc «Zaporizhskloflus». https://www.steklo-flus.com [in Ukrainian and English].2. GOST 5632–75 High alloy steels and corrosion-proof, heat-resisting and heat-treated alloys. Types. official publication. Moscow, IPC Standards Publishing [in Russian].

3. PJSC «Dneprospetsstal». Brand and specialized assortment. http://www.dss-ua.com/rus/product/grades/steel.wbp?catalog.root-node-id=01577d88-7f00-0001-01b9-ce4be05a547a [in Russian].

4. GOST 7565–81 Iron, steel and alloys. Sampling for determination of chemical composition. Moscow, Standardinform [in Russian].

5. GOST 7564–97 Rolled products. General rules of sampling, rough specimens and test pieces selection for mechanical and technological testing. Minsk, Euro-Asian Council for standardization, metrology and certification [in Russian].

6. GOST 18968–73 Rods and strips of corrosion-resisting and heat-resisting steels for steam turbine blades. Technical conditions. Moscow, Euro-Asian Council for standardization, metrology and certification [in Russian].

7. GOST 1778–70 Steel. Metallographic methods for the determination of non-metallic inclusions. Moscow, State Standard of the USSR Union [in Russian].

8. Lisova, L.O., Stovpchenko, G.P., Goncharov, I.O. et al. (2020) Thermodynamics of interaction and physical properties of 30CaF2/30CaO/30Al2O3 system slags with addition of SiO2 and MgO in different ratios in electroslag remelting. Suchasna elektrometalurgiya, 1, 8-13 [in Ukrainian]. https://doi.org/10.37434/sem2020.01.01

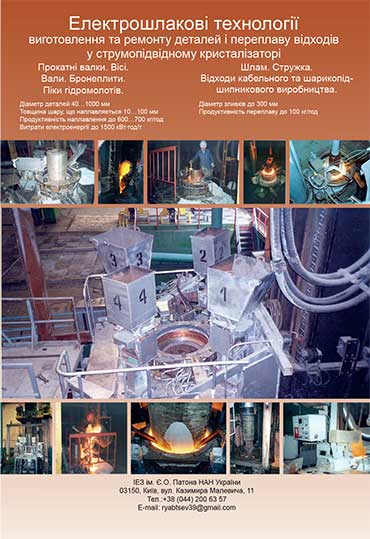

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.