| 2020 №03 (01) |

DOI of Article 10.37434/sem2020.03.02 |

2020 №03 (03) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2020, #3, 18-23 pages

Metal carbonization with different methods of ESR of non-compacted steel chips

Yu.M. Kuskov, O.G. Kuzmenko

E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: office@paton.kiev.ua

Abstract

Investigations of metal carbonization at remelting of chips of four types of steels (high-speed, stamping, hightemperature, structural) and a high-temperature alloy were performed. It was found that carbonization of electroslag metal depends both on chemical composition of steel (alloy), and on technological features of melting. The latter include remelting technique, method and degree of chips cleaning, composition of the used fluxes and temperature conditions of chips melting in the slag. In most of the cases, carbonization is determined chiefly by presence of LCL remains in the chips. It is shown that application of current-conducting electrode-mould is recommended for chips remelting, which allows simplifying the remelting process after achievement of maximum carbonization of the metal. Ref. 15, Tabl. 7.

Keywords: chips; electroslag remelting; consumable and nonconsumable electrodes; slag; cleaning; carbonization

Received 07.07.2020

References

1. Kochkin, S.V. (2015) Development of technology of metal strip recycling by electroslag remelting method. web.snauka.ru/issuses/2015/06/53989 [in Russian].2. (2017) State statistics service of Ukraine. Economical statistics. Economical activity. Environment. http://www.ukrstat.gov.ua/operativ/menu/menu_u/ns.htm [in Ukrainian].

3. Kuskov, Yu.M. (2001) Electroslag remelting of waste of different enterprises using nonconsumable water-cooled electrode. Elektrometallurgiya, 2, 24–28 [in Russian].

4. Biktagirov, F.K. (2003) Application of non-consumable electrode electroslag process for melting, refining and treatment of metals. Report 2. Advances in Electrometallurgy, 1, 4–8.

5. Zherebtsov, S.N. (2012) Application of technology of electroslag remelting of high-alloyed steels and alloys for producing of measuring billet. Elektrometallurgiya, 4, 32–34 [in Russian].

6. Pershin, P.S. (1962) Cast tool. Moscow-Sverdlovsk, Mashgiz [in Russian].

7. Revis, I.A., Lebedev, T.A. (1972) Structure and properties of cast cutting tool. Leningrad, Mashinostroenie [in Russian].

8. Voronin, A.E., Latash, Yu.V., Nikolaev, V.A. et al. (1976) Investigation of carbonizing of metal during electroslag process with graphitized electrode. Spec. Elektrometallurgiya, 32, 22–27 [in Russian].

9. Volkotrub, N.P., Lyuty, I.Yu., Voronin, A.E., Krutikov, R.G. (1978) Peculiarities of the process of cast iron carburizing in electroslag treatment. Ibid., 37, 24–30 [in Russian].

10. Voronin, A.E., Latash, Yu.V., Biktagirov, F.K. et al. (1984) Influence of steel composition on carbon distribution between slag and metal in electroslag treatment. Ibid., 57, 12–17.

11. Yakovenko, V.A., Lyuty, I.Yu. (1985) Examination of wear of graphitized electrodes in electroslag process. Problemy Spets. Elektrometallurgii, 1, 19–24 [in Russian].

12. Yakovenko, V.A., Latash, Yu.V., Lyuty, I.Yu., Konotop, V.F. (1989) Wear of electrodes of different carbon materials under conditions of electroslag process. Ibid., 1, 25–28 [in Russian].

13. Davydov, A.K., Goncharov, A.E., Soloviov, G.I., Marfitsin, V.V. (1997) Electroslag surfacing by graphite electrode. Svarochn. Proizvodstvo, 6, 47–48 [in Russian].

14. Gokhman, G.Z., Volkov, A.E., Ksyondzyk, G.V., Kuskov Yu.M. (1985) Electroslag remelting of high-speed steel. Spets. Elektrometallurgiya, 58, 55–62 [in Russian].

15. Medovar, B.I., Tsykulenko, A,K., Bogachenko A.G., Litvinchuk, V.M. (1982) Electroslag technology abroad. Kiev, Naukova Dumka [in Russian]

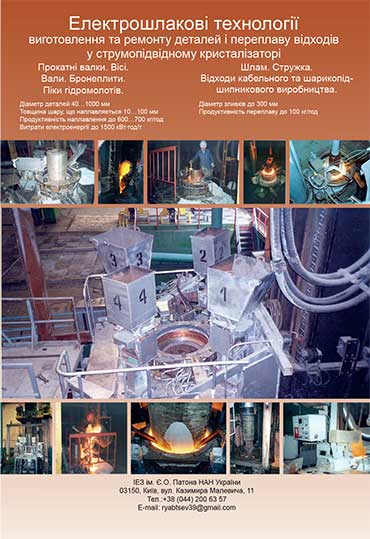

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.