| 2023 №03 (01) |

DOI of Article 10.37434/sem2023.03.02 |

2023 №03 (03) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2023, #3, 9-12 pages

Producing steel-copper hearth-level electrode for DC arc furnaces

F.K. Biktagirov, V.O. Shapovalov, O.V. Hnatushenko, A.P. Ignatov, V.V. Barabash, T.I. Hrishchenko

E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: office@paton.kiev.uaAbstract

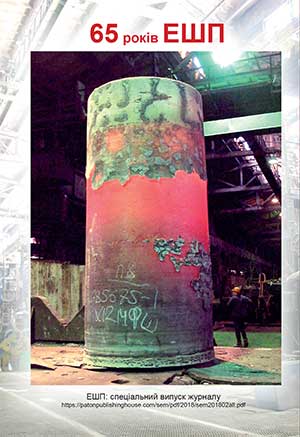

Technology of electroslag surfacing of steel with copper for products of a large cross- section and copper thickness was developed. Surfacing is performed with electroslag preheating of the steel billet surface to a temperature higher than copper melting temperature, but lower than that of steel melting. Then the steel-copper transition layer is formed by feeding copper into the slag pool in the liquid state or in the form of solid discrete filler. This is followed by deposition of a copper layer of the required thickness. Slags with different melting temperature were developed for each surfacing stage. It is shown that electroslag surfacing ensures a strong bonding with minimal penetration of iron into copper. Bimetal steel-copper billets of rod-type hearth-level electrodes with the copper part of 320 mm diameter and 450 mm height were produced for 12 ton DC ASF. 9 Ref., 7 Fig.

Keywords: bimetal, steel-copper, electroslag surfacing, transition layer, quality, hearth-level electrode

Received 10.08.2023

References

1. Lopukhov, G.A. (2004) Hearth electrode of DC arc steel furnace of Danieli Company design. Elektrometallurgiya, 6, 48??51 [in Russian].2. Gensini, G., Pavlicevic, M. (1994) Cooled bottom electrode for direct current electric furnace. Danieli & Co Off. Mec. Spa (Italy). Priority data 05.11.1994. Patent US 5651024. H05B 7/06. www.espacenet.com

3. Zaitsev, V.A., Medovar, L.B., Tishchenko, P.I. et al. (2011) Using two-circuit electroslag remelting for producing steel-copper blanks for anodes of DC arc furnaces. Advances in Electrometallurgy, 2, 63‒68.

4. Zaitsev, V.A., Medovar, L.B. (2009) Hearth electrode of DC arc furnaces. Sovrem. Elektrometallurgiya, 2, 3–8.

5. Tishchenko, P.I., Timoshenko, S.N., Onishchenko, S.P. (2012) Hearth electrodes DSPPT. Review of main technical solutions [in Russian] http://uas.su/articles/steelmaking/2012/00001.php

6. Tishchenko, P.I., Tishchenko, A.P., Timoshenko, S.N., Fridman, M.A. (2012) Hearth electrode of DC arc furnaces. Metallurgicheskaya i Gornorudnaya Promyshlennost, 7, 282–284 [in Russian].

7. Lychko, I.I. (1969) Electroslag cladding of copper and its alloys on steel. Kyiv, UkrNIINTI [in Russian].

8. Lychko, I.I. (1978) Flat electroslag cladding of copper and its alloys on steel. In: Welding and cladding of heavy nonferrous metals. Kyiv, PWI, 40–42 [in Russian].

9. Pasichnyk, S.Yu., Pasechnik, A.Yu., Korytskyi, G.G. (2014) Method of electroslag cladding of copper and its alloys on steel. Pat. UA 104262 [in Ukrainian].

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.