| SCIENTIFIC AND TECHNICAL | |||

|

Paton B.E., Gvozdetsky V.S., Krivtsun I.V., Zagrebelny A.A., Shulym V.F. and Dzheppa V.L.

Hybrid laser-microplasma welding of thin sections of metals. | 2 | ||

| Prototype of an integrated plasmatron for microplasma, laser and laser-microplasma welding of different metals up to 3 mm thick in the automatic and manual modes was designed and manufactured. Technological cababilities of this plasmatron for welding steels, titanium and aluminium alloys in the microplasma, laser and hybrid modes were studied. The efficiency of utilisation of energy of the laser beam and microplasma arc combined in a hybrid process was proved to substantially increase. Laser-microplasma welding using the microplasma arc with alternating-polarity current pulses is shown to have a high potential for joining aluminium alloys. | |||

|

Kirian V.I. and Mikhoduj L.M.

Problems in application of new steels of increased and high strength in welded structures. | 7 | ||

| Peculiar features of formation of structure and properties of welded joints of sparsely-alloyed structural steels of the new generation are described. The importance of a careful approach to the selection of materials and processes of their welding to prevent the susceptibility of weld metal and HAZ to brittle fractures. Principal problems of analysing a delayed fracture of welded joints of these steels are considered. | |||

|

Makhnenko V.I. and Saprykina G.Yu.

Role of mathematical modelling in solving problems of welding dissimilar steels (Review). | 14 | ||

| Considered are the main aspects of problems associated with fusion welding of steels of the austenitic and ferritic-pearlitic grades. Analysis of calculations and ways of solving the problems for each of the above grades are based on studies published lately. The role of mathematical modelling in solving the above problems is shown. | |||

|

Golodnov A.I. and Khvortova M.Yu.

Experimental investigations of fields of residual stresses in welded and rolled I-beams. | 26 | ||

| Stress-strain state of I-beams was determined using experimental data. Method of preliminary stress inducing to I-beams by a local thermal effect allowing increase in load-carrying capacity of compressed I-beam columns and improvement in structure of steel in the HAZ zones forming in fabrication of welded I-beams was suggested. | |||

|

Pokhmursky V.I., Student M.M., Dovgunyk V.M. and Sidorak I.I.

Flux-cored wires of FeCrB+Al and FeCr+Al+C systems for electric arc metallizing. | 28 | ||

| The electric arc metallizing can be effectively used for restoration of worn-out surfaces of machine parts at relatively small expenses. The use of flux-cored or composite wires widens significantly the application of this technological process. However, the need appears here in optimizing composition of electrode wires and improvement of system of their spraying. | |||

| INDUSTRIAL | |||

|

Paton V.E., Voropaj N.M. and Gvozdetsky V.S.

A system for mechanized microplasma welding of honeycomb aluminium metal structures. | 32 | ||

| The paper deals with the design principles and features of all-purpose and specialised microplasma welding equipment. Examples of application of mechanised units in fabrication of unique open honeycomb metal structures of thin aluminium are given. | |||

|

Tyurin Yu.N., Zhadkevich M.L., Gubenko B.G. and Kolisnichenko O.V.

Features of pulsed-plasma alloying of the surface of iron-base alloys. | 37 | ||

| A technology of surface alloying, based on the use of high-speed pulsed-plasma jets and electric discharges has been studied. In this case, electric current of 3 to 5 kA is passed through the jet. Alloying material in the form of a rod or wire is fed into the plasma jet. The high speed of the metal-containing plasma jet and the interaction of its pulses with the electromagnetic field, provide mixing of the alloy with the partially-melted surface of the item. As a result, the studied coating has no pores or any clearly-defined boundary with the base. | |||

|

Bernadsky V.N.

Japan determines its priorities in the field of welding for XXI century. | 42 | ||

| The paper presents systematised comments of specialists of the Japan Welding Society on determination of the national priorities in the field of welding science and technology at the beginning of the XXI century. Considering the "technological saturation" of the majority of the welding processes, applied on a mass scale, the recommendations are to predominantly develop those technologies, that have a significant potential, in particular, an arc welding process - A-TIG, friction stir welding (FSW), laser and laser-hybrid technologies. The main scientific problem, namely weldability and nature of cracking, is still urgent. The determinant role of computer modelling in research, design and development of welded structures, technologies and welding consumables, has been established unambiguously. | |||

|

Sidorov I.N., Gradovich A.A., Kislitsky A.A., Rozhkov V.V., Strukov A.V., Chapaev I.G. and Lavrenyuk P.I.

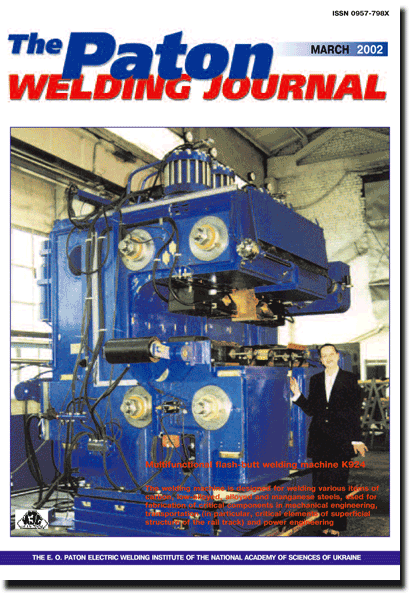

Unit for resistance welding of nuclear reactor fuel elements. | 45 | ||

| The paper analyses the experience of development and application of highly efficient equipment for sealing fuel elements in WWER type reactors, using resistance welding. A two-position unit, that simultaneously processes two fuel elements in the automatic mode, has been developed on the basis of ASSK automatic welding machines and is being used successfully. The operation of the unit is provided by control system, pneumatic system, system of pumping down and filling the fuel elements with helium, as well as welding power source that are common for both the welding heads. These units were the basis to develop highly efficient automated lines for welding and sealing the fuel elements. | |||

| BRIEF INFORMATION | |||

|

Khaskin V.Yu. and Garashchuk V.P.

Laser cladding of hypoeutectoid complexly-alloyed steels. | 48 | ||

| Process of laser alloying of steels 25Kh1M2FTR and 40KhN2MFA was investigated. Technology for strengthening surfaces of workpieces operating at high temperatures in aggressive environments was developed, providing an extension of their service life by more than 1.5-2 times. It was established that the laser alloying with a mixture of chromium and relite powders provided an increase of several times in wear resistance of hypoeutectoid complexly-alloyed steels and in their heat resistance from 400 to about 1000 oC. | |||

|

Borisov Yu.S. and Kislitsa A.N.

Microplasma spraying using wire materials. | 50 | ||

| A microplasma method of coating deposition using wires has been developed. Specifications of the MPN-004 unit with an attachment for microplasma spraying using wires are presented. Parameters of the process of microplasma spraying depending on the wire material are determined. Microstructures of tungsten and copper coatings, obtained by this method, are given. | |||

| NEWS | |||

| Visit by the Extraordinary and Plenipotentiary Ambassador of the Russian Federation in Ukraine to the STC "E.O. Paton Electric Welding Institute" of the NAS of Ukraine. | 52 | ||

|

ADVERTISING.

| 54

| | |

(You are viewing the simplified file contents)

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.