| 2023 №02 (07) |

DOI of Article 10.37434/as2023.02.01 |

2023 №02 (02) |

"Avtomatychne Zvaryuvannya" (Automatic Welding), #2, 2023, pp. 3-9

Improvement of technology of producing Ti-TiC modifiers and studying their impact on the structure of deposited metal of type 25Kh5FMS

L.M. Lobanov1, O.M. Syzonenko2, I.O. Ryabtsev1, M.O. Pashchyn1, A.A. Babinets1, I.P. Lentyugov1, A.S. Torpakov2, O.L. Mikhoduj1, T.G. Solomiichuk1

1E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: office@paton.kiev.ua2Institute of Pulse Processes and Technologies of the NAS of Ukraine. 43a Bohoyavlensky Ave., 54018, Mykolaiv, E-mail: dioo@iipt.com.ua

The technology of producing Ti-TiC modifiers was improved, which reduced the average diameter of its particles by more than 6 times. The use of the proposed processing procedure made it possible to produce a Ti-TiC powder with at least 20 % of TiC in its composition. It was found that for the investigated modes, processing in kerosene is more effective in terms of dispersion than processing in ethanol. The use of the produced powder as a modifier at its content in a deposited metal 25Kh5FMS at the level of 0.01 %, leads to a significant change in the microstructure and its conversion from a columnar into a cellular one. In terms of the possibility to control the structure and properties of the deposited metal, the most promising is the use of modified Ti-TiC powders of H2 and H4 type, which were produced as a result of high-voltage processing of the mixture of corresponding powders in a hydrocarbon fluid using a voluminous-distributed multi-spark discharge mode. This provides a significant effect on the structure of the deposited metal of type 25Kh5FMS, but at the same time does not lead to the formation of microcracks in the deposited metal. 12 Ref., 1 Tabl., 5 Fig.

Keywords: modification, technology of producing modifiers, high-voltage processing, hydrocarbon fluid, arc surfacing, fluxcored wire, deposited metal, structure of deposited metal, non-metallic inclusions

Received: 28.12.2022

References

1. Babinets, A.A., Ryabtsev, I.O. (2021) Influence of modification and microalloying on deposited metal structure and properties (Review). The Paton Welding J., 10, 3-10. https://doi.org/10.37434/tpwj2021.10.012. Gladky, P.V., Mikaelyan, G.S. (1992) Microalloying and modification of wear-resistant deposited metal. Deposited metal. Composition, structure, properties. Kyiv, PWI, 33-36 [in Russian].

3. Babinets, A.A., Ryabtsev, I.O., Lentyugov, I.P., Bogaichuk, I.L. (2022) Influence of microalloying with boron on the structure and properties of deposited metal of the type of tool steel 25Kh5FMS. The Paton Welding J., 6, 3-11. https://doi.org/10.37434/tpwj2022.06.01

4. Krivchikov, S.Yu. (2012) Modification by boron of deposited metal of white cast iron type. The Paton Welding J., 6, 19-21.

5. Maksimov, S.Yu., Machulyak. V.V., Sheremeta, A.V., Goncharenko, E.I. (2014) Investigation of influence of microalloying with titanium and boron of weld metal on its mechanical properties in underwater welding. The Paton Welding J., 6-7, 76-79. https://doi.org/10.15407/tpwj2014.06.15

6. Kuznetsov, V.D., Stepanov, D.V. (2015) Structure and properties of weld metal modified by nanooxides. The Paton Welding J., 11, 10-16. https://doi.org/10.15407/tpwj2015.11.01

7. Stepnov, K.K., Matvienko, V.N., Oldakovsky, A.I. (2011) Modification of medium-chromium deposited metal. The Paton Welding J., 8, 10-12.

8. Pu, J., Yu, Sh., Li, Yu. (2017) Effects of Zr-Ti on the microstructure and properties of flux aided backing submerged arc weld metals. J. of Alloys and Compounds, 692, 351-358. https://doi.org/10.1016/j.jallcom.2016.09.045

9. Syzonenko, О.М., Prokhorenko, S.V., Lypyan, E.V. et al. (2020) Pulsed discharge preparation of a modifier of Ti-TiC system and its influence on the structure and properties of the metal. Materials Sci., 56, 2, 232-239. ISSN 1068-820X (Print), 1573-885X (Electronic). https://doi.org/10.1007/s11003-020-00421-1

10. Lypyan, E.V., Syzonenko, O.N., Torpakov, A.S., Zdanov, A.A. (2015) Thermodynamical analysis of heterogeneous chemical reactions in system "mixture of Fe-Ti powders - hydrocarbon liquid" under the action of high-voltage electric discharges. Visnyk NTU KhPI. Seriya: Tekhnika ta Elektrofi zyka Vysokykh Naprug. Kharkiv, 51, 1160, 59-65 [in Russian].

11. Sizonenko, O.N., Tregub, V.A., Lipyan, E.V. (2015) Analysis of physico-technical processes in high-voltage electric-discharge treatment of metal powders. Vestnik Ukr. Mater. Obshchestva, 8, 10-21 [in Russian].

12. Goldshtejn, M.I., Grachev, S.V., Veksler, Yu.J. (1985) Special steels. Moscow, Metallurgiya, 308-309

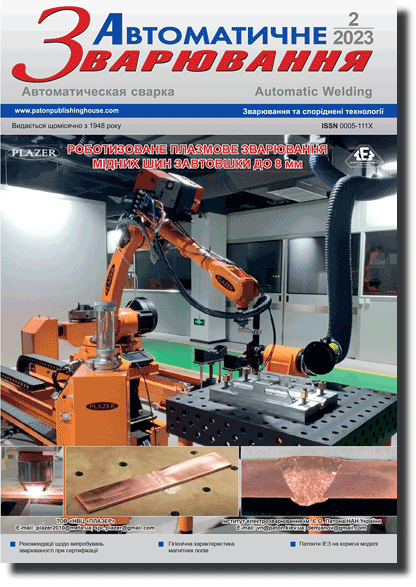

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.