| 2021 №10 (02) |

DOI of Article 10.37434/as2021.10.03 |

2021 №10 (04) |

"Avtomatychne Zvaryuvannya" (Automatic Welding), #10, 2021, pp. 19-28

Corrosion-mechanical resistance of 2219 alloy welded joints, under simulated service conitions

L.I. Nyrkova1, T.M. Labur1, Ye.I. Shevtsov2, O.P. Nazarenko2, A.V. Dorofeev2

1E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: office@paton.kiev.ua

2SC «DB Pivdenne». 3 Kryvorizhska Str., 49008, Dnipro

ДWe studied the corrosion resistance, including local corrosion resistance, of welded joints of aluminium alloy 2219, made by nonconsumable electrode single-pass welding along (L) and across (Acr) the rolling stock heat-treated to Т81 condition. It is shown that resistance of welded joints of 2219 alloy to general and local corrosion in amyl and its vapours does not depend on the direction of billet rolling in welding. An increase of ductility and strength of welded joint samples was found after soaking them in amyl and amyl vapours. The coefficient of welded joint strength after soaking in amyl rises from 0.65 up to 0.67 in the longitudinal direction, and from 0.64 to 0.66 in the transverse direction. After soaking in amyl vapours, the strength properties of the welded joint almost do not change: strength coefficient was the same in both the orientation directions and it was equal to 0.64. Fracture ran along the line of fusion of the weld with the base metal, where melting of grain boundaries and their thickening take place during the thermal cycle of welding at solidification, as well as decomposition of copper solid solution in aluminium, which is accompanied by precipitation and coagulation of the strengthening phases. 23 Ref., 2 Tabl., 6 Fig.

Keywords: 2219 aluminium alloy, welded joints, heat treatment, corrosion resistance, mechanical properties, microstructure, mechanical fracture at tension

Received: 27.08.2021

References

1. Rao, P.S., Sivadasan, K.G., Balasubramanian, P.K. (1996) Structure-property correlation on AA 2219 aluminium alloy weldments. Bulletin of Materials Science, 19 (3), 549-557. https://doi.org/10.1007/BF027448272. Li, H., Zou, J., Yao, J., Peng, H. (2017) The effect of TIG welding techniques on microstructure, properties and porosity of the welded joint of 2219 aluminum alloy. Journal of Alloys and Compounds, 727, 531-539. https://doi.org/10.1016/j.jallcom.2017.08.157

3. Zhang, D., Wang, G., Wu, A. et al. (2019) Study on the inconsistency in mechanical properties of 2219 aluminium alloy TIG-welded joints. Journal of Alloys and Compounds, 777, 1044-1053. https://doi.org/10.1016/j.jallcom.2018.10.182

4. Grilli, R., Baker, M.A., Castle, J.E. et al. (2010) Localized corrosion of a 2219 aluminium alloy exposed to a 3.5% NaCl solution. Corrosion Science, 52 (9), 2855-2866. https://doi.org/10.1016/j.corsci.2010.04.035

5. Zhang, D., Wu, A., Zhao, Y. et al. (2021). Effects of the Number of Welding Passes on Microstructure and Properties of 2219-C10S Aluminum Alloy TIG-Welded Joints. Journal of Materials Engineering and Performance, 5, 3537-3546. https://doi.org/10.1007/s11665-021-05655-x

6. Wan, Z., Meng, D., Zhao, Y. et al. (2021) Improvement on the tensile properties of 2219-T8 aluminum alloy TIG welding joint with weld geometry optimization. Journal of Manufacturing Processes, 67, 275-285. https://doi.org/10.1016/j.jmapro.2021.04.062

7. Niu, L.Q., Li, X.Y., Zhang, L. et al. (2017) Correlation between microstructure and mechanical properties of 2219-T8 aluminum alloy joints by VPTIG welding. Acta Metallurgica Sinica (English Letters), 30 (5) 438-446. https://doi.org/10.1007/s40195-016-0516-9

8. Zhang, D.K., Wang, G.Q., Wu, A.P. et al. (2019) Effects of Post-weld Heat Treatment on Microstructure, Mechanical Properties and the Role of Weld Reinforcement in 2219 Aluminum Alloy TIG-Welded Joints. Acta Metallurgica Sinica (English Letters), 32 (6), 684-694. https://doi.org/10.1007/s40195-018-00869-w

9. Gupta, R.K., Panda, R., Mukhopadhyay, A.K. et al. (2015) Study of aluminum alloy AA2219 after heat treatment. Metal Science and Heat Treatment, 57 (5), 350-353. https://doi.org/10.1007/s11041-015-9888-0

10. Lu, Y., Wang, J., Li, X. et al. (2018) Effects of pre-deformation on the microstructures and corrosion behavior of 2219 aluminum alloys. Materials Science and Engineering: A, 723, 204-211. https://doi.org/10.1016/j.msea.2018.03.041

11. Chen, S., Li, F., Liu, Q. et al. (2020) Effect of Post-aging Heat Treatment on Strength and Local Corrosion Behavior of Ultrafine-Grained 2219 Al Alloy. Journal of Materials Engineering and Performance, 29 (5), 3420-3431. https://doi.org/10.1007/s11665-020-04818-6

12. Zhang, D., Li, Q., Zhao, Y. et al. (2018) Microstructure and mechanical properties of three-layer TIG-welded 2219 aluminum alloys with dissimilar heat treatments. Ibid, 27 (6), 2938-2948. https://doi.org/10.1007/s11665-018-3394-7

13. Zhu, Z.Y., Deng, C.Y., Wang, Y. et al. (2015) Effect of post weld heat treatment on the microstructure and corrosion behavior of AA2219 aluminum alloy joints welded by variable polarity tungsten inert gas welding. Materials & Design (1980-2015), 65, 1075-1082. https://doi.org/10.1016/j.matdes.2014.10.056

14. Peng, X.N., Qu, W.Q., Zhang, G.H. (2009) Influence of Welding Processes on Mechanical Properties of Aluminum Alloy 2219 [J]. Journal of Aeronautical Materials, 2, 57-60

15. Bai, J.Y., Yang, C.L., Lin, S.B. et al. (2016) Mechanical properties of 2219-Al components produced by additive manufacturing with TIG. The International Journal of Advanced Manufacturing Technology, 86 (1), 479-485. https://doi.org/10.1007/s00170-015-8168-x

16. Rao, S.K., Reddy, G.M., Rao, K.S. et al. (2005) Reasons for superior mechanical and corrosion properties of 2219 aluminum alloy electron beam welds. Materials characterization, 55 (4-5), 345-354. https://doi.org/10.1016/j.matchar.2005.07.006

17. АМS-QQ-А-250/30А. Specifications. Aluminium alloy 2219. Sheet and plate [in Ukrainian].

18. GOST 7512-82: Nondestructive testing. Welded joints. Radiography method [in Ukrainian].

19. GOST 9.908-85: Unified system of corrosion and ageing protection. Metals and alloys. Methods for determination of corrosion and corrosion resistance indices [in Russian]. 20. GOST 9.904-82: Unified system of corrosion and ageing protection. Aluminium alloys. Accelerated test method for exfoliating corrosion [in Russian].

21. GOST 9.021-74: Unified system of corrosion and ageing protection. Aluminium and aluminium alloys. Accelerated test method for intercrystalline corrosion [in Russian].

22. GOST 1497-84 (ISO 6892-84, СТ CMEA 471-88) Metals. Methods of tension test [in Russian].

23. GOST 9.502-82 (СТ CMEA 6194-88) Unified system of corrosion and ageing protection. Inhibitors of metals corrosion for aqueous systems. Methods of corrosion tests (with modifications Nos 1, 2) [in Russian].

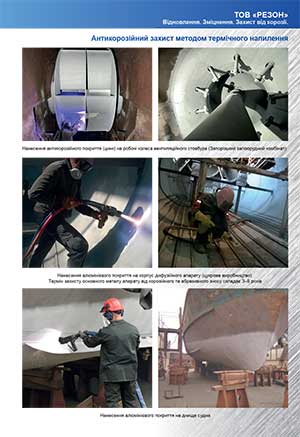

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.