| 2024 №02 (03) |

DOI of Article 10.37434/as2024.02.04 |

2024 №02 (05) |

"Avtomatychne Zvaryuvannya" (Automatic Welding), #2, 2024, pp. 22-25

Structure and mechanical properties of titanium alloy GRADE 12 – carbon steel 16 Mn bimetal obtained by explosion welding

P.S. Shlonskyi, Feng Gao

Liaoning Xin Huayang Weiye Equipment Manufacturing company Ltd № 1 Road, Tieling high-tech industrial development zone, Liaoning provice, China. E-mail: shlensk@ukr.netThe quality of the bimetal produced by explosion welding is affected by the mechanical characteristics of flying plate material. For development of explosion welding modes, a study of the structure and mechanical properties of titanium alloy Grade 12 (TA10, flying plate) + carbon steel 16 Mn (09G2S) bimetal was conducted. The thickness of the titanium alloy plates was 5 and 6 mm, the mechanical properties, namely the relative elongation in as-delivered condition for these plates differed by 15 %. The results on tear and shear strength of titanium alloy-carbon steel bimetal are given. In the case of titanium alloy TA10 it is demonstrated that for plates with a lower relative elongation, the strength of the joint produced by explosion welding is lower. Bending test showed no delamination for two thicknesses of the titanium alloy. Also, for the two thicknesses of the titanium alloy, the joint zone has a microstructure characteristic for explosion welding. 8 Ref., 4 Tabl., 7 Fig.

Keywords: explosion welding, titanium-steel bimetal, mechanical properties

Received: 26.01.2024

Received in revised form: 15.03.2024

Accepted: 25.03.2024

References

1. Kudiniv V.М., Koroteev А.Ya. (1978) Explosion welding in metallurgy. Moscow, Metallurgy. [in Russian].2. Lysak V.I., Kuz’min S.V. (2005) Explosion welding. Moscow, Mechanical engineering. [in Russian].

3. Deribas А.А. Phisics of hardening and explosionwelding (1980) Novosibirsk. Science. [in Russian]

4. Zheng Yuanmou (2002) Explosive Welding and Metal Cladded Materials as well as the Engineering Applications, Central South University Press, Changsha.

5. Wang Yaohua (2007) Researches and Practices on Explosive Welding of Metal Sheets, National Defense Industry Press, Beijing.

6. HAN Xiao-min, WANG Shao-gang, HUANG Yan et al. (2015) Interfacial Microstructure and Mechanical Properties of TA10-Q345R Composite Plate with Explosive Welding. Doi: 10.3969/j.issn. 1001–4837. 2015.06.004 Titanium academics J., Nanjing, 6, 32, 24–29.

7. Findik, F. (2011) Recent developments in explosive welding. Materials and Design, 32 (3), 1081-1093. https://doi.org/10.1016/j.matdes.2010.10.017

8. L.I. Markashova, V.V. Arsenyuk, G.M. Grigorenko (2002) Features of phase formation during pressure welding of dissimilar metals under high-speed deformation conditions. Automatic welding, 9, 12-17. [in Russian].

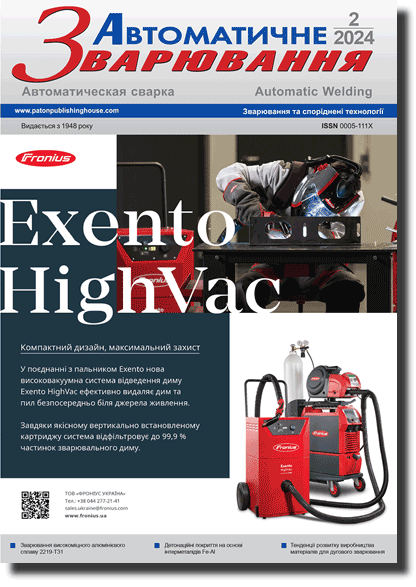

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.