| 2023 №11 (09) |

DOI of Article 10.37434/as2023.11.01 |

2023 №11 (02) |

"Avtomatychne Zvaryuvannya" (Automatic Welding), #11, 2023, pp. 5-22

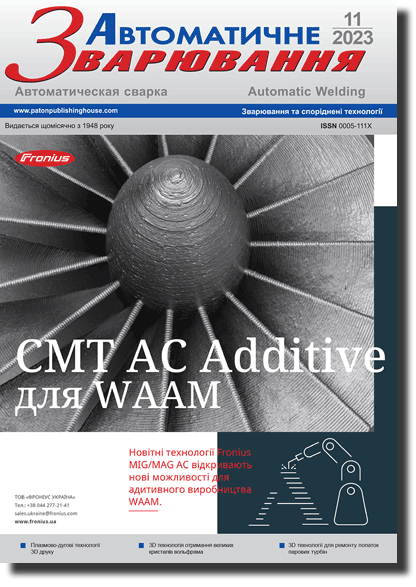

Plasma-arc technologies of additive surfacing (3D printing) of spatial metal products: application experience and new opportunities

V.M. Korzhyk1, А.А. Grynyuk1, V.Yu. Khaskin1, О.M. Voytenko1, О.M. Burlachenko1, О.О. Khuan3

1E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: office@paton.kiev.ua2E.O. Paton Institute of Materials Science and Welding, National Technical University of Ukraine “Igor Sikorsky Kyiv Polytechnic Institute”. 37 Beresteiska Ave., Kyiv, 03056, Ukraine.

3Paton Research Institute of Welding Technologies in Zhejiang Province: People’s Republic of China, Zhejiang Province, Hangzhou City, Xiaoshan District, St. Shixing Beilu 857, office. 426.

The growing relevance of 3D printing of finished metal products in recent years is due to the reduction of costs for manufacturing, machining, changing the standard sizes and nomenclature of parts, the possibility of obtaining solid parts with complex internal geometry. One of the most promising 3D printing processes, which provides a wide range of productivity (0.02 - 25 kg/h and more) with the possibility of surfacing a wall with a thickness of 2-20 mm, is additive plasma-arc surfacing (APDN) with wires and powder materials. The work examines the current state of research on additive manufacturing of metal parts from steels and alloys, determines the state and prospects for the development of APDN. It is shown that APDN allows performing 3D printing using a wide range of implant materials, in particular, compact and composite (powder) wires, powders of light alloys and refractory metals, composite powders and mechanical mixtures of powders of alloys, metal ceramics, carbides, borides, etc. New opportunities for the application of APDN include development of technologies for growing products from materials with gradient functional properties, from dissimilar materials, with accompanying modification of the deposited metal by additional processing, improving the properties of the deposited metal due to the use of hybrid processes. The state of innovative developments of APDN technologies and equipment carried out at the E.O. Paton Electric Welding Institute of the National Academy of Sciences of Ukraine, and their industrial implementation is highlighted. 32 Ref., 5 Tabl., 22 Fig.

Keywords: additive manufacturing, 3D printing, plasma arc surfacing, steel, nickel, aluminum, titanium alloys, structure, mechanical properties, gradient functional properties, equipment.

Received: 26.10.2023

References

1. Laue, R., Colditz, P., Möckel, M., Awiszus, B. (2022) Study on the milling of additive manufactured momponents. Metals, 12, 1167. https://doi.org/10.3390/met120711672. Antonysamy, A.A. (2012) Microstructure, texture and mechanical property evolution during additive manufacturing of Ti6Al4V alloy for aerospace applications: Microstructure. University of Manchester, faculty of Engineering and Physical Sciences.

3. Peleshenko, S., Korzhyk, V., Voitenko, O. et al. (2017) Analysis of the current state of additive welding technologies for manufacturing volume metallic products (review). Eastern European J. of Enterprise Technologies, 3/1(87), 42-52. https://doi.org/10.15587/1729-4061.2017.99666

4. Kvasnytskyi, V., Korzhyk, V., Lahodzinkyi, I. et al. (2020) Creation of volumetric products using additive arc cladding with compact and powder filler materials. Proceedings of the 2020 IEEE 10th International Conference on «Nanomaterials: Applications and Properties», 9-13 Nov, NAP 2020, 9309696. https://doi.org/10.1109/NAP51477.2020.9309696

5. Korzhik, V.N., Khaskin, V.Yu., Grinyuk, A.A. et al. (2016) 3D-printing of metallic volumetric parts of complex shape based on welding plasma-arc technologies (Review). The Paton Welding J., 5-6, 117-123. https://doi.org/10.15407/tpwj2016.06.20

6. Ge, J., Lin, J., Lei, Y., Fu, H. (2017) Location-related thermal history, microstructure, and mechanical properties of arc additively manufactured 2Cr13 steel using cold metal transfer welding. Materials Science & Engineering: A, 715, 144-153. https://doi.org/10.1016/j.msea.2017.12.076

7. Alberti, E.A., Bueno, B., D'Oliveira, A.S. (2015) Additive manufacturing using plasma transferred arc. The International J. of Advanced Manufacturing Technology, 83, 9-12. https://doi.org/10.1007/s00170-015-7697-7

8. Colegrove, P., Williams, S. (2013) High deposition rate high quality metal additive manufacture using wire + arc technology. Cranfield University. Режим доступу: URL: https:// www.xyzist.com/wp-content/uploads/2013/12/Paul-Colegrove-Cranfield-Additive-manufacturing.pdf

9. Özel, Т., Shokri, H., Loizeau, R. (2023) A review on wirefed directed energy deposition based metal additive manufacturing. J. Manuf. Mater. Process., 7(1), 45. https://doi.org/10.3390/jmmp7010045

10. Korzhik, V.N., Vojtenko, A.N., Peleshenko, S.I. et al. (2017) Development of automated equipment for manufacturing 3D metal products based on additive technologies. The Paton Welding J., 5-6, 79-85. https://doi.org/10.15407/tpwj2017.06.15

11. Alhuzaim, A.F. (2014) Investigation in the use of plasma arc welding and alternative feedstock delivery method in additive manufacture: Master of Science General Engineering. Montana Tech. of the University of Montana.

12. Alaluss, K., Mayr, P. (2019) Additive manufacturing of complex components through 3D plasma metal deposition - A simulative approach. Metals, 9(5), 574. https://doi.org/10.3390/met9050574

13. Geng, H., Li, J., Xiong, J. et al. (2017) Geometric limitation and tensile properties of wire and arc additive manufacturing 5A06 aluminum alloy parts. J. of Materials Engineering and Performance, 26, 621-629. https://doi.org/10.1007/s11665-016-2480-y

14. Gnatenko, M., Chigileichik, S., Sakhno, S. (2021) Manufacture of aviation parts from heat-related nickel alloys by multilayer plasma surfacing. Aerospace Technic and Technology, 5(175), 48-52. https://doi.org/10.32620/aktt.2021.5.06

15. Gnatenko, M., Zhemaniuk, P., Petrik, I. et al. (2019) Detecting the influence of heats sources on material properties when production a aviation parts by a direct energy deposition method. Eastern-European j. of enterprise technologies, 1(12(97)), 49-55. https://doi.org/10.15587/1729-4061.2019.157604

16. Gnatenko, M., Naumyk, V., Matkovska, M. (2019) Influence of sources of heating and protective gases on the properties of the material obtained by the direct deposition. Materials Science and Technology, 68-74. https://doi.org/10.7449/2019/MST_2019_68_74

17. Grinyuk, A.A., Korzhik, V.N., Shevchenko, V.E. et al. (2015) Main tendencies in development of plasma-arc welding of aluminium alloys. Тhe Paton Welding J., 11, 31-41. https://doi.org/10.15407/tpwj2015.11.04

18. Bai, J.Y., Yang, C.L., Lin, S.B. et al. (2016) Mechanical properties of 2219-Al components produced by additive manufacturing with TIG. Int. J. Adv. Manuf. Technol., 86, 479- 485. https://doi.org/10.1007/s00170-015-8168-x

19. Qi, Z., Cong, B., Qi, B. et al. (2018) Microstructure and mechanical properties of double-wire + arc additively manufactured Al- Cu-Mg alloys. J. of Materials Processing Technology, 255, 347- 353. https://doi.org/10.1016/j.jmatprotec.2017.12.019

20. Lin, Z., Song, K., Yu, X. (2021) A review on wire and arc additive manufacturing of titanium alloy. J. of Manufacturing Processes, 70, 24-45. https://doi.org/10.1016/j.jmapro.2021.08.018

21. Hoefer, K., Mayr, P. (2018) Additive manufacturing of titanium parts using 3D plasma metal deposition. Materials Science Forum, 941, 2137-2141. https://doi.org/10.4028/www.scientific.net/MSF.941.2137

22. R'ıos, S., Colegrove, P.A., Williams, S.W. (2019) Metal transfer modes in plasma wire + arc additive manufacture. J. of Materials Processing Tech, 264, 45-54. https://doi.org/10.1016/j.jmatprotec.2018.08.043

23. Lin, J.J., Lv, Y.H., Liu, Y.X. et al. (2016) Microstructural evolution and mechanical properties of Ti-6Al-4V wall deposited by pulsed plasma arc additive manufacturing. Materials & Design, 102, 30-40. https://doi.org/10.1016/j.matdes.2016.04.018

24. Kelly, S.M., Kampe, S.L. (2004) Microstructural evolution in laser-deposited multilayer Ti-6Al-4V builds: Part II. Thermal Modeling. Metall Mater. Trans.: A, 35(6), 1869-1879. https://doi.org/10.1007/s11661-004-0095-7

25. Xu, F.J., Lv, Y.H., Xu, B.S., Liu, Y.X. (2013) Effect of deposition strategy on the microstructure and mechanical properties of Inconel 625 superalloy fabricated by pulsed plasma arc deposition. Mater., 45, 446-455. https://doi.org/10.1016/j.matdes.2012.07.013

26. Martinaa, F., Mehnen, J., Williams, S.W. et al. (2012) Investigation of the benefits of plasma deposition for the additive layer manufacture of Ti-6Al-4V. J. of Materials Processing Technology, 212(6), 1377-1386. https://doi.org/10.1016/j.jmatprotec.2012.02.002

27. Colegrove, P.A., Martina, F., Roy, M.J. et al. (2014) High pressure interpass rolling of wire + arc additively manufactured titanium components. Advanced Materials Research, 996, 694-700. https://doi.org/10.4028/www.scientific.net/AMR.996.694

28. Wu, B., Ding, D., Pan, Z. et al. (2017) Effects of heat accumulation on the arc characteristics and metal transfer behavior in wire arc additive manufacturing of Ti6Al4V. J. of Materials Processing Technology, 250, 304-312. https://doi.org/10.1016/j.jmatprotec.2017.07.037

29. Wua, B., Pana, Z., Dingb, D. et al. (2018) The effects of forced interpass cooling on the material properties of wire arc additively manufactured Ti6Al4V alloy. J. of Materials Processing Technology, 258, 97-105. https://doi.org/10.1016/j.jmatprotec.2018.03.024

30. Reisgen, U., Sharma, R., Oster, L. (2019) Plasma multiwire technology with alternating wire feed for tailor-made material properties in wire and arc additive manufacturing. Metals, 9(7), 745. https://doi.org/10.3390/met9070745

31. Qi, Z., Cong, B.Q., Qi, B. et al. (2018) Microstructure and mechanical properties of 1 double-wire + arc additively manufactured Al-2 Cu-Mg alloys. J. of Material Processing Technology, 255, 347-353. https://doi.org/10.1016/j.jmatprotec.2017.12.019

32. Korzhyk, V.M., Grynyuk, A.A., Khaskin, V.Yu. et al. (2023) Influence of the speed of plasma-arc welding at a variable polarity asymmetrical current on the formation of joints of high-strength aluminium alloys. The Paton Welding J., 8, 17-28. https://doi.org/10.37434/tpwj2023.08.02

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.