| 2020 №02 (08) |

DOI of Article 10.37434/sem2020.02.01 |

2020 №02 (02) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2020, #2, 3-9 pages

Investigation of the technological features and admissible pressures of the process of vacuum ESR

I.V. Protokovilov, D.A. Petrov, V.B. Porokhonko

E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: office@paton.kiev.ua

Abstract

The paper presents the results of experimental studies of the features of vacuum electroslag remelting process at remelting of steel and titanium consumable electrodes in a chamber-type electroslag furnace, using fluoride-oxide and salt fluxes. It was found that pressure lowering in the furnace melting space results in decrease of melting current, increase of its oscillation amplitude and subsequent violation of the stability of the electroslag process, caused by slag pool boiling. It was determined that the critical pressure level, at which pool boiling occurs, depends on flux composition and electric modes, determining the power of the ESR process. For salt fluxes of AN-T1 and AN-T4 type, the critical pressure level is equal to approximately 12...22 and 15...26 kPa, respectively, and for ANF-1, ANF-6, ANF-28 fluoride-oxide fluxes it is 3...15 kPa. It is shown that the higher is the remelting power, the higher the pressure, at which flux boiling occurs. Ref. 12, Tabl. 1, Fig. 5.

Keywords: electroslag remelting; chamber furnace; vacuum; flux; boiling; melting current; voltage

Received 16.03.2020

References

1. Medovar, L.B., Troyansky, A.A., Saenko, V.Ya. et al. (2005) About new approach to designing of ESR chamber furnaces. Advances in Electrometallurgy, 2, 15-17.2. Medovar, L.B., Lebed, V.A., Stovpchenko, A.P. et al. (2012) About reconstruction of ESR furnaces. Sovrem. Elektrometall. 4, 3-6 [in Russian].

3. Scholz, H., Biebricher, U., Carosi, A., Pocci, D. (2004) An advanced pressurized electroslag remelting process approach at laboratory scale. In: Proc. of 7th Int. Conf. on High Nitrogen Steels (Ostend, Belgium), 317-322.

4. Krylov, S.A., Evgenov, A.G., Shcherbakov, A.I., Makarov, A.A. (2016) New pressure electroslag furnace DEShP-0.1: Mastering and prospects of development. Trudy VIAM, 5, 28-35 [in Russian].

5. Krylov, S.A., Evgenov, A.G., Makarov, A.A., Tonysheva, O.A. (2017) Ingot of pressure electroslag remelting. Trudy VIAM, 51(3). URL: http://viam-works.ru/ru/articles?art_ id=1076 [in Russian]. https://doi.org/10.18577/2307-6046-2017-0-3-3-3

6. Krylov, S.A., A.G., Makarov, A.A., Tonysheva, O.A., Mosolov, A.N. (2018) Investigation of influence of consumable electrode quality on technological process of pressure electroslag remelting of high-nitrogen steels. Trudy VIAM, 69(9), 3-11 [in Russian]. https://doi.org/10.18577/2307-6046-2018-0-9-3-11

7. ALD vacuum technologies. Electro slag remelting processes and furnaces (2018). https://www.ald-vt.com/wp-content/uploads/ 2018/04/ESR_Electro_Slag_Remelting.pdf

8. Radwitz, S., Scholz, H., Friedrich, B. (2013) Investigation of slag compositions and pressure ranges suitable for electroslag remelting under vacuum conditions. In: Proc. of the Intern. Symp. on Liquid Metal Processing & Casting (September 22-25, 2013, Austin, Texas), 87-93. https://doi.org/10.1007/978-3-319-48102-9_12

9. Yu Liu, Zhao Zhang, Guangqiang Li et al. (2018) Investigation of fluoride vaporization from CaF2-CaO-Al2O3 slag for vacuum electroslag remelting. Vacuum, 158, 6-13. https://doi.org/10.1016/j.vacuum.2018.09.027

10. Yu Liu, Xijie Wang, Guangqiang Li et al. (2019) Cleanliness improvement and microstructure refinement of ingot processed by vacuum electroslag remelting. J. of Materials Research and Technology. https://www.jmrt.com.br/en-pdf-S223878541931484X'); ?>

11. Yu Liu, Xijie Wang, Guangqiang Li et al. (2018) Role of vacuum on cleanliness improvement of steel during electroslag remelting. Vacuum, 154, 351-358. https://doi.org/10.1016/j.vacuum.2018.05.032

12. Xuechi Huang, Baokuan Li, Zhongqiu Liu, Mengzhen Li (2020) Numerical study on the effect of vacuum on oxygen transfer in electroslag remelting process. Ibid., 172. https://doi.org/10.1016/j.vacuum.2019.109069

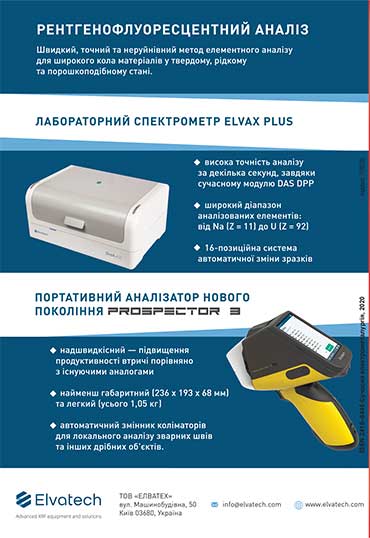

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.