| 2020 №02 (06) |

DOI of Article 10.37434/sem2020.02.07 |

2020 №02 (08) |

"Suchasna Elektrometallurgiya" (Electrometallurgy Today), 2020, #2, 39-43 pages

High-temperature mechanical properties of β-stabilized intermetallic alloy of TiAl system after induction zone melting

L.M. Lobanov, E.A. Asnis, N.V. Piskun, I.I. Statkevich

E.O. Paton Electric Welding Institute of the NAS of Ukraine. 11 Kazymyr Malevych Str., 03150, Kyiv, Ukraine. E-mail: office@paton.kiev.ua

Abstract

Intermetallic β-stabilized alloy of TiAl−Ti–44Al–5Nb–3Cr–1.5Zr (at. %) system, which was obtained by electron beam melting was investigated. The cast alloy blanks were re-remelted by the method of induction crucibleless zone melting. This processing method is one of the most attractive for improving the structure of the ingot, which, in its turn, significantly improves the mechanical properties of the alloy. The paper describes the equipment for hightemperature mechanical testing of the alloy. Such mechanical characteristics as yield strength, tensile strength, degree of deformation during compression, as well as the modulus of elasticity and creep rate in the initial state and after ICZM were determined. Deformation curves were plotted from these data. The test results showed that ICZM led to a significant improvement of the high-temperature characteristics of Ti–44Al–5Nb–3Cr–1.5Zr alloy. Ref. 15, Tabl. 1, Fig. 5.

Keywords: intermetallic alloy; TiAl system; high-temperature mechanical tests; mechanical characteristics; strength; yield; degree of deformation; creep; elasticity

Received 04.06.2020

References

1. Appel, F., Paul, J.D.H., Oering, M. (2011) Gamma titanium aluminide alloys: Science and technology. WILEY-VCH, Weinheim. https://doi.org/10.1002/97835276362042. Glotka, T.A., Perepelkina, M.N., Omelchenko, O.S. (2016) The mechanical properties of complex alloyed titanium alloy, obtained by intensive plastic deformation. Construction. Materials science. Mashinostroenie. Series: Starodubov readings, 90, 71-77 [in Russian].

3. Friedman, L.B. (1974) Mechanical properties of metals. Moscow, Mashinostroenie [in Russian].

4. Inozemtsev, A.A., Bashkatov, I.G., Karyakovtsev, A.S. (2010) Modern titanium alloys and problems of their development. Moscow, VIAM, 60-67 [in Russian].

5. Antashev, V.G., Nochovnaya, N.A., Shiryaev, A.A. et al. (2011) Prospects for the development of new titanium alloys. Vestnik MGTU im. N.E. Bauman, 2, 60-67 [in Russian].

6. Antonyuk, S.L., Molyar, A.G., Kalinyuk, A.N. et al. (2003) Titanium alloys for the aviation industry of Ukraine. Advances in Electrometallurgy, 1, 9-12.

7. Povarova, K.B., Bannykh, O.A. (1999) Principles of the construction of structural alloys on the basis of intermetallides. Pt 1. Materialovedenie, 2, 27-32 [in Russian].

8. Lobanov, L.M., Asnis, E.A., Piskun, N.V., Statkevich, I.I. (2018) Improvement of the structure and mechanical characteristics of structural intermetallics of titanium-aluminium system at directional solidification. Dopovidi NANU, 12, 51-60 [in Russian]. https://doi.org/10.15407/dopovidi2018.12.051

9. Brun, M.Ya., Soldatenko, I.V., Bykova, L.A. (1992) Structure and mechanical properties of new heat-resistant titaniunm alloy VT25U. MiTOM, 1, 29-31 [in Russian]. https://doi.org/10.1007/BF00768708

10. Kartavykh, A.V., Asnis, E.A., Piskun, N.V. et al. (2017) Room-temperature tensile properties of float-zone processed β-stabilized γ-TiAl(Nb, Cr, Zr) intermetallic. J. Materials Letters, 188, 88-91. https://doi.org/10.1016/j.matlet.2016.10.103

11. Kartavykh, A.V., Asnis, E.A., Piskun, N.V. et al. (2015) Microstructure and mechanical properties control of γ-TiAl(Nb, Cr, Zr) intermetallic alloy by induction float zone processing. J. Alloys Compd., 643, 182-186. https://doi.org/10.1016/j.jallcom.2014.12.210

12. Kartavykh, A.V., Asnis, E.A., Piskun, N.V. et al. (2016) A promising microstructure/deformability adjustment of β-stabilized γ-TiAl intermetallics. J. Materials Letters, 162, 180-184. https://doi.org/10.1016/j.matlet.2015.09.139

13. GOST 8817-82: Metals. Upsetting test method [in Russian].

14. GOST 25.503-97: Calculations and strength tests. Methods of mechanical testing of metals. Compression test method [in Russian].

15. Kartavykh, A.V., Cherdyntsev, V.V., Stepashkin, A.A., Gorshenkov, M.V. (2013) High-temperature dilatometry of heat-resistant alloy Ti-46Al-8N. Metally, 4, 62-69 [in Russian]. https://doi.org/10.1134/S0036029513070082

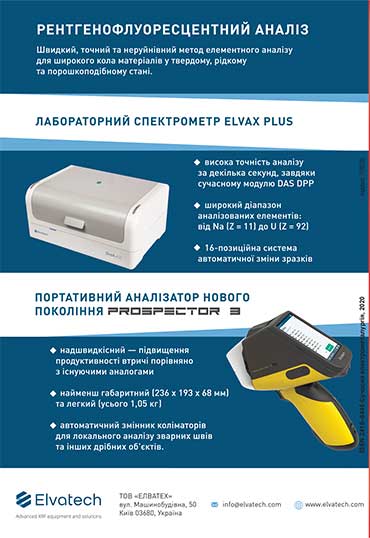

Advertising in this issue:

The cost of subscription/purchase order journals or individual articles

| Journal/Currency | Annual Set | 1 issue printed |

1 issue |

one article |

| TPWJ/USD | 384 $ | 32 $ | 26 $ | 13 $ |

| TPWJ/EUR | 348 € | 29 € | 24 € | 12 € |

| TPWJ/UAH | 7200 UAH | 600 UAH | 600 UAH | 280 UAH |

| AS/UAH | 1800 UAH | 300 UAH | 300 UAH | 150 UAH |

| AS/USD | 192 $ | 32 $ | 26 $ | 13 $ |

| AS/EUR | 180 € | 30 € | 25 € | 12 € |

| SEM/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| SEM/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| SEM/EUR | 120 € | 30 € | 25 € | 12 € |

| TDNK/UAH | 1200 UAH | 300 UAH | 300 UAH | 150 UAH |

| TDNK/USD | 128 $ | 32 $ | 26 $ | 13 $ |

| TDNK/EUR | 120 € | 30 € | 25 € | 15 € |

AS = «Automatic Welding» - 6 issues per year;

TPWJ = «PATON WELDING JOURNAL» - 12 issues per year;

SEM = «Electrometallurgy Today» - 4 issues per year;

TDNK = «Technical Diagnostics and Non-Destructive Testing» - 4 issues per year.